How to choose a reliable building vibrator

Concrete is one of the most common materials in construction. Buildings of various purposes and foundations for them, columns, bridges and other structures are erected from it. Concrete is made from a mixture of sand, cement, crushed stone of different fractions and water. The originally prepared solution has heterogeneous structure: there is a lot of air in it. When the monolith hardens, this leads to the formation of voids (cavities), which at least 20% reduces the strength of the constructed structure.

Vibrator for concrete allows using the oscillatory effect to make the working solution more fluid, compactly pack sand with rubble. At the same time, the available air reaches the surface, and the filler itself is evenly distributed. The initial volume of the solution poured into the formwork is reduced by about a third as a result of vibrotamping.As a result, the shells are practically absent, which maximizes the strength characteristics of the monolith.

Content

Device and principle of operation of the tool

Despite the presence of different types of concrete vibrators, their device is similar. The following key equipment components can be identified:

- drive unit;

- unbalance (unbalanced);

- transmission shaft;

- vibrotip.

Common structural elements for different types of vibrators are contained in the photo below.

Drive unit - This is the node through which useful work is done. He sets in motion the balancers and the shaft. Directly poured concrete acts vibrotip (aka vibula of boom). Depending on the type of vibrator, its shape is different. The following varieties of this node are distinguished by this criterion:

- vibrocaps;

- vibroplips;

- vibro cores

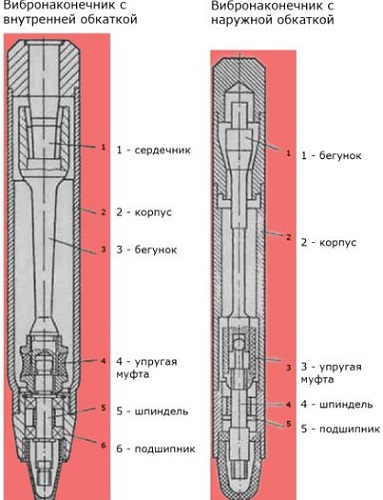

The shape of the vibrotip depends on the area of work performed with concrete, as well as their volume. The design of two types of vibrator heads is presented in the photo below.

The use of unbalances allows to receive vibrations (vibrations) of various frequencies, which are transmitted to the vibrotip via the shaft.

Deep (internal) vibrators are equipped with a flexible shaft. Its length determines the maximum depth that the equipment used can affect when vibrating ramming a concrete solution. Flexible shaft, driven by the engine, is a steel cable, covered with rubber or plastic sheath.

Principle of operation Concrete vibrators of various types are reduced to the impact on the working solution of vibrations. This leads to compaction of the filler (crushed stone, sand) and air extrusion. The structure of tamped concrete becomes more uniform, its density and strength properties increase.

Classification of vibrators for concrete

The market vibrator is represented by a variety of models. All the variety of commercially available equipment for tamping a concrete solution can be divided into individual types according to the followingcriteria:

- type of drive installed;

- created level (frequency) of oscillations;

- the method of tamping mortar.

The tool also shares by power On such groups:

- low-power and medium-power (up to 2 kW), which is suitable for domestic and semi-professional use;

- powerful (professional, from 2 to 4 kW capacity), designed for continuous, long-term use in the construction of reinforced concrete structures.

Low and medium power equipment is cheaper than professional models. It also has a light weight (up to 20 kg) and compact dimensions, which makes it easy to transport. The mass of industrial analogues sometimes reaches 100 kg.

By type of installed drive

There are the following types of vibrators for concrete:

- electromechanical;

- pneumatic;

- with an internal combustion engine (motor);

- hydraulic.

Electric vibrator (electromechanical) is a vibrating equipment operating from the network, equipped with a single-phase or three-phase asynchronous type electric motor (the rotor is short-circuited). In this case, the balance with the eccentric is connected to the ends of the motor shaft.Such models are widely used, but they are inferior in terms of power, as well as the degree of their autonomy to fuel (diesel, gasoline) units.

Other types of electric models also include submersible-type cordless rammers. They are mobile, like fuel analogues, but are more compact and weigh less.

Pneumatic vibrator It is also a popular type of concrete ramming equipment. Its operation is caused by the action of compressed air supplied by a compressor unit. Such units are used mainly in industrial conditions. Depending on the type of rotational oscillator installed on the equipment, a pneumatic ball vibrator and a roller vibrator are distinguished.. Vibration parameters are regulated by the on (off) valve.

The pneumatic tool is additionally completed with devices for working with wooden and metal types of formwork, as well as a flexible shaft.

Motor units work on gasoline or diesel fuel. They have a high level of autonomy, high power.

Deep Vibrator petrol CHAMPION

Hydraulic tool It consists of a hydraulic pump, flow control systems and operating pressure. Adjustment allows you to set the frequency of vibrations according to the requirements.

The frequency of oscillation

According to this criterion, vibrators are divided into the following types:

- low frequency;

- midrange;

- high frequency.

Have low frequency models the frequency of vibration is up to 3500 oscillations per minute with a large amplitude. Such devices are used for ramming concrete solutions with fillers of large fractions characterized by a low degree of mobility.

ODWERK BVR 350 Low Frequency Deep Vibrator

Medium Frequency Aggregates - it is a universal option for performing work with various types of concrete mortars (especially with medium-grained rubble). At the same time, the frequency of operating oscillations is within the range of 3500-10000 vibrations per minute.

High Frequency Immersion Vibrator (and superficial) gives out more than 10,000 oscillations per minute with a small amplitude. Such equipment is intended for tamping of the working solution with fine-grained filler.

The high-frequency deep vibrator for AGP VRN1400 concrete

By way of interaction of concrete mass

According to the method of compacting concrete equipment is divided into the following types:

- deep (submersible);

- external (superficial).

Deep Vibrator for concrete it produces tamping of the mass of mortar by immersion in its thickness of a vibrotip. The latter can be connected to the drive directly or through a flexible shaft.

Surface vibrator for concrete in the solution is not immersed. In this case, the oscillatory effect is transmitted through the structural elements of the formwork or directly from the upper layers of the fill to the bottom. Vibration generated by the technique also affects the substrate.

Surface models are used when a submersible vibrator for concrete is not suitable, for example, because of the small dimensions of the structure being erected, due to the frequent installation of reinforcing bars.

Important characteristics for choosing a vibrator

Choosing the type of vibrator for concrete suitable for performing the required work, one should be guided by the following technical characteristics of the instrument:

- vibration frequency with amplitude;

- plant capacity;

- weight;

- the shape and size of the vibrotip (the criterion is important only for deep-water apparatuses);

- shaft length;

- seal diameter

The last three parameters are important if you have to use the deep vibrator.

The amplitude of oscillations is related to their frequency: the smaller the first parameter, the higher the second, and the converse is true. High-frequency installations should be purchased if, in most cases, concrete mortars with small fractional fillers are to be tamped with. Mid-frequency units better condense medium-grained compositions, and low-frequency - coarse. Medium-frequency oscillating seals will also be a good option for home use.

From power performance depends. To work in life, enough tool 750-1500 watts. Professional activity requires the use of units of 2 kW power.

Hand tool suitable in private construction: because of the small weight (up to 6 kg) they can work one person. It is also convenient for transportation and storage. Powerful, professional vibration systems allow you to perform a significant amount of work, but the operation of the units requires the involvement of several people in the process.

Dimensions of vibrotip affect the freedom of its progress inside the solution.This factor must be taken into account when working with reinforced structures. To seal the concrete fill without reinforcing bars, it is better to use wide tips (up to 110 mm in diameter). This will increase equipment performance.

From flexible shaft length the depth of immersion of the vibrating tip in the poured concrete solution depends. A tool with a short shaft is not suitable for the construction of massive structures, because it is not possible to properly tamp concrete. This will reduce the quality of the frozen monolith.

Seal diameter - it is a parameter that determines the distance by which vibrations from the vibrotip diverge. The larger this parameter, the more productive the equipment used, because at one time a larger volume of the filled mixture can be compacted.

An important factor in the choice is the price: the higher it is, the, in most cases, the better and more durable equipment.

Recommendations on the type of engine installed

Here you should consider the following factors:

- the required degree of autonomy of the work;

- distance from the mains;

- explosive working conditions;

- equipment performance;

- upcoming fill volumes.

Pneumatic tool You can buy if you have a lot of work. It should be borne in mind that for its normal operation requires continuous flow of air, the temperature of which must correspond to the value specified in the operating instructions.

To enjoy power tools, access to a single-phase or three-phase network is required (depending on the type of motor installed). This is not always possible under construction conditions for various reasons. But from the point of view of price and performance, it is possible to choose the equipment that is optimal in terms of technical characteristics, both for home and professional use.

Fuel aggregates - This is the best choice in terms of mobility. You can choose a model of the required capacity for different types of work.

Overview of manufacturers and prices

Concrete compactors produces a lot of both domestic and foreign firms. Among Russian manufacturers are the following:

- Caliber;

- Red Lighthouse;

- Energomash.

Products of these companies are considered to be optimal in terms of price to quality. With its production characteristics, it is not inferior to foreign models from the category corresponding in parameters.So, a concrete vibrator with an electric motor for household use with a capacity of 0.75 to 1.2 kW and a 30-50 mm diameter vibrating tip, is between 4000-5000 rubles, for example, Energomash BV-71101.

Vibrator Energomash BV-71101

Tool with more power (from 1.3 to 2 kW), with a working tip with a diameter of 38-51 mm and a length of flexible shaft 4 m from the companies Red Beacon or Energomash is sold at a price of 13,000-16,000 rubles, for example, Red Beacon EPK-1300.

Deep vibrator Red Beacon EPK-1300

Of foreign manufacturers are popular among buyers of products of such brands:

- Makita;

- Wacker Neuson;

- DDE;

- Sturm.

Japanese makita company offers a fairly wide selection of cordless power tools in the price range of 14,000–32,000 rubles, for example, a portable vibrator with a Makita BVR450Z battery pack.

Makita BVR450Z vibrator

Deutsch Wacker Neuson brand known for its professional high frequency concrete compaction tools. The cost of such products starts from 40,000 rubles (for example, Wacker Neuson IREN 38).

Deep vibrator Wacker Neuson IREN 38

Equipment Chinese companies Sturm and DDE is a budget option:

- models with a capacity from 0.85 to 1 kW, equipped with a vibrating-tip with a flexible shaft, can be purchased at a cost of 4,000 rubles;

- the average price of devices for 2 kW is in the range of 9000-15000 rubles.

The choice of building vibrator should be approached with regard to the volume of upcoming work operations. For home use, it is enough to buy mid-frequency models of Chinese or domestic production, but regular work requires the purchase of a professional tool.. If network access at a construction site is not a problem, then it will be cheaper to acquire electrical models of the required performance. When mobility is important, units operating on gasoline or diesel fuel will be required, and in case of infrequent use, battery products will also be suitable in some cases.

/rating_on.png)

/rating_off.png)