How to choose a wall chaser for concrete

Modern standards of construction and interior decoration require the installation of most utilities. in a hidden way. Water and heat supply pipelines, electrical and informational network cables must be hidden in the walls, ceiling or floor. In this form, they have no effect on the interior, which was appreciated by the master of repair and building owners. There is a special tool, called a wall chaser, which allows you to quickly and smoothly make a suitable shape in the solid surface of the recess. They are laid wires or pipes, followed by sealing rough coatings. Choosing a wall chaser for concrete, you need to know the principle of its work and navigate in the range of major manufacturers.

Content

Features of the wall chaser

A wall chaser is a hand-held power tool that looks like an angle grinder. It is specifically designed for electrical and plumbing work. It can be made in concrete, brick and other solid building materials long and even furrows of a given size. Structurally, it consists of:

- electric motor;

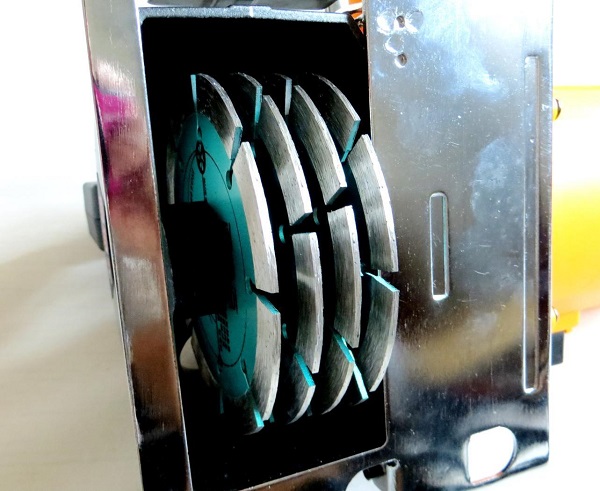

- rotating spindle with two abrasive discs mounted on it;

- guide frame with rollers, allowing to reach a pre-set cutting depth;

- convenient handles for holding the tool and its direction by the operator;

- protective casing.

Most modern models work with vacuum cleanercollecting dust and dust, which improves the working conditions of staff. The most powerful units are equipped with special devices. with water supply to the cut zone.

This not only reduces the dustiness of the room, but also prolongs the use of replacement parts by cooling and wetting the cutting edges.

Disks as abrasion easily replaced with new ones. The gap between them is governed by the installation of rings of different sizes.Most wall chaser-chisellers provide chrombing up to 30 mm, but there is equipment for 50 mm. If a furrow of greater width is required, it is performed in two passes.

Use a wall chaser simple enough. The operator moves the tool along the pre-made markup. In this case, two narrow parallel grooves remain in the wall or on the floor. The material between them is easily removed with skarpel, chisel or perforator.

Types of wall chasers

Depending on the hardness of the material in which it is necessary to make a strobe, different efforts are required. For aerated concrete is enough power of human hands. At the same time using the simplest devices for foam blocks, made in the form of scrapers with comfortable handles. Manual mechanical burs no rotating parts at all. For wood, usually any manual or electric cutting tool is used for wood.

It should be remembered that according to current regulations in wooden buildings any electrical cable must be laid in the outer way.

In all other cases, the choice of the wall chaser stops at manual electric models, differing technical features and engine power. All models are conventionally divided into:

- small;

- average;

- big ones.

Shtroborez Einhell TH-MA 1300

The first of them are characterized by light weight, not exceeding 4 kg, equipped with discs with a diameter of 115 or 125 mm and a rotational speed of 8000-10000 revolutions per minute. Engine power in such an instrument can be up to 1400 watts. For the latter category are characteristic: weight more than 8 kg, disc diameter 230 mm, power up to 2600 watts. Medium category wall chasers occupy an intermediate position. They work with disks 150 and 180 mm.

Tools of any type can be used for gas blocks, bricks and concrete. The difference will concern only the speed of passage and the depth of cut.

Alternative designs for wall chasers

High efficiency and performance is different milling wall chaser. It can be used to perform a groove of any section without additional operations. The main working element of it is not an abrasive disc, but a mill of especially high-quality alloys based on tungsten rotating at a speed from 1000 to 1400 revolutions per minute. It is characterized by high speed of passage, but cannot be applied on high-strength concrete grades.

Exist multidiset wall chaser, the width of the grooves which is determined by the number of installed in a row of several diamond disks. Such a tool is applied to the material of any hardness, immediately forming a furrow of the required size.

Some masters like single-disk wall chaser, which is an improved grinder.

Unlike other hand tools, wall chasers are not driven by internal combustion engines. This would weigh their own weight so much that it would be impossible to work on weight when the walls are broken. Due to the relatively high power consumption of professional wall chaser, the battery version of their execution also did not find wide application. Therefore, in the construction or repair of remote objects where there is no stationary power supply network, use gasoline generatorproviding the power tool with the necessary amount of energy.

Main criteria for selecting a wall chaser

To choose the right wall chaser you need to have a clear idea of the tasks that will have to be solved. This takes into account the intensity of use, the mechanical properties of the material of the walls or floor,the nature of the laid communications. First of all, pay attention to the objective specifications tools, which include:

- motor power, directly related to performance;

- own weight;

- maximum width and depth of cut;

- design features used discs.

A well-known manufacturer pays special attention to the protection of workers from negative factors associated with the use of the tool, and to improve its reliability. Industrial wall chaser should certainly have a connection to a vacuum cleaner, allowing you to work without dust.

An experienced master, purchasing a tool with two discs, is sure to ask the seller about the availability of the following auxiliary devices in the selected model and additional functions:

- systems of automatic power setting while maintaining the set speed depending on the resistance level of the material being processed;

- automatic overload protection;

- motor off functions when brushes are worn;

- clutch system that protects the tool in case of jamming of the discs;

- soft starters;

- protection against accidental activation;

- constructive solutions that reduce vibration.

Important features that will influence your choice will also be:

- ease of tool setting and consumables replacement;

- direction of movement at work (to yourself or from yourself);

- availability of a case for laying a wall chaser and accessories;

- ease of holding in working position.

In order not to make a fatal mistake, it is better to trust the suppliers of products famous brands. Drawing attention to these aspects, you will be able to choose a tool that you can use as efficiently as possible.

/rating_off.png)