Types of heating elements in convectors

Convector - It is a device used for heating residential premises. The design involves the use of its own heating element for heating the room. This allows you to bypass the mediation of any coolant, making the heating element for the convector the central part of the unit. That is why systems without water or oil as an intermediary, they are taken out to a separate class. The modern circuit assembly of the convector allows for efficient operation at a rather low temperature of the heater.

Content

Types of heating elements

Electric convector (there is also gas and water) is the most popular heating device on the market today.He earned his reputation not only with ease of handling, but also with reliability. This equipment is able to provide comfortable conditions both in the living room and in the public area. The main feature of the design experts believe the absence of intermediaries for heat transfer.

In modern convector use one of three types of heating elements.. He might be:

- needle, ribbon-shaped, stich-type heater;

- a tubular type electric heater with aluminum fins, abbreviated as TEN;

- monolithic type.

Each type has its own characteristics and disadvantages. The decision on which one to choose should be made based on the characteristics of the heated room.

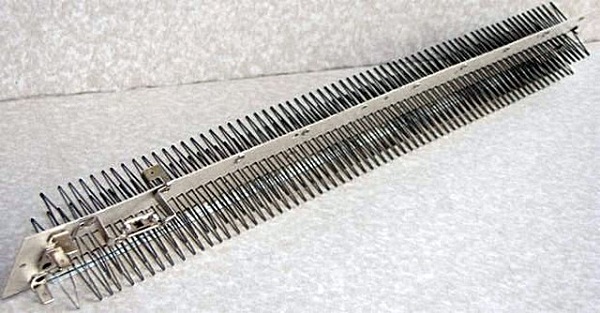

Needle type heating elements

Needle heaters (also called tape heaters) are a plate made of dielectric material. A chrome-nickel thread is attached to it, forming loops on each side. It is a conductive heating element and is covered insulating varnish.

A characteristic feature of the needle element is the high temperature of the heater. At the same time, this type of device has the lowest inertia of heat, which means almost instantaneous heating and cooling.

Heat transfer in convectors using a needle element occurs mostly through the housing. A vulnerable point of such devices can be called a heating thread that is practically not protected from moisture. Covered with a layer of insulating varnish, it easily deteriorates from the ingress of water. This circumstance makes needle heaters completely unsuitable for use in bathrooms and rooms with high humidity. The attractive side of a convector with a needle-type heating element is the price: the cost of such equipment is one and a half times lower than that of a similar device.

Needle type heater

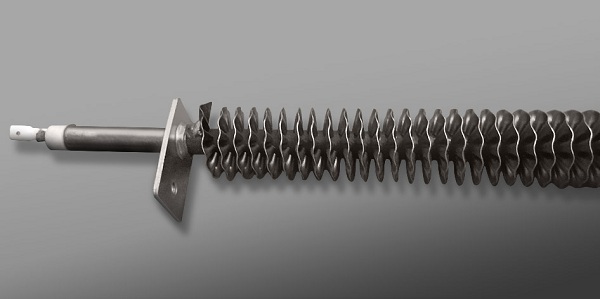

Tubular type heating elements

The tubular heater is made of nichrome threadintegrated into a quartz tube with steel. In addition, the design provides for magnesium backfill with attached to it. aluminum fins. The ribs perform the functions of a heat exchanging element.

Most often, the shape and distribution of the fins plates is special for each company, but this does not affect the function of the ribs. The advanced design of such a diffuser of aluminum makes it possible to achieve an intense heat transfer from the heating element to air masses and to make the convection process more efficient.

The heat of these elements is much lower than that of the needle ones, however they are more unpretentious and reliable.

For the most part, heaters with tubular heaters are protected from moisture penetration, which allows them to be installed in the bathroom. Despite this, it is not recommended to install the device closer than 1 meter from the water source.

Tubular type heater

Monolithic type heating elements

Monolithic type heating elements are used for convector with degree of protection IP 24. They have a nichrome thread with a filler of a dielectric material. All the "stuffing" is packed in a cast aluminum case with metal fins.

During heating and cooling, each detail of the monoblock increases and narrows in volume.This feature allows you to avoid friction, as well as the development of microcracks. A good monolithic convector is noiseless, very reliable and durable. The monolithic body minimizes the intermediate heat loss, and also reduces the heating of the costal structure.

Monolithic type heater

Which convector to choose

If we talk about which heater is better to choose, the answer will be ambiguous. With all the obvious advantages, each type has its drawbacks. For example, a tubular element has the longest glow time. With active work, he can make clicking sounds and squeaks caused by the expansion of the structure. In turn, the monolithic element deters most customers with its high cost. Not everyone is ready to overpay for a significant degree of protection and minimal heat loss.

Most often, consultants in stores recommend purchasing convectors with a monolithic element or heating elements.

The decision on which convector is more efficient should be made on the basis of the characteristics of the heated room.

- If the room is not wet, and the rate of warming up the air does not play a key role, an ordinary heating element is best.

- However, if it is necessary to constantly maintain comfortable conditions indoors, it would be better to give preference to the monolithic element. An efficient convection system allows you to save a little on electricity.

- You can also turn your attention to combined type models, as infrared heater with convection function. This device combines heating by means of heating elements and an infrared element, which makes it possible to achieve a fast warming up of the room with an insignificant consumption of electrical energy.

Experts advise to pay attention not only to the heating element. Maximum work powerThe spatial arrangement, mobility and ergonomics of the hull also contribute significantly to efficiency. Carefully study the technical characteristics of the device, and you can easily choose the convector that suits you.

/rating_on.png)

/rating_half.png)

/rating_off.png)