Original accessories for electric drills

Few users know that an ordinary drill can perform very unusual functions besides drilling. For these purposes, there are very original accessories for the drill that can expand its scope of application. Consider the types of nozzles and attachments that turn a drill into a completely different unit, capable of performing unusual functions at the household level.

Content

Stops

This type of fixture is most widely represented and has many interpretations.

- Drilling stop. On the auxiliary handle for an electric drill there is a metal rod with metric divisions - this is the limiter that rests against the wall or the workpiece and prevents the drill bit from penetrating deeper.

- Shutter speed parallel. This tool is more perfect - it can control the depth of the future hole and the correct location of the tool, used for perpendicular drilling during construction. There are models where dust removal is simultaneously carried out using a connected vacuum cleaner. The prefix can be made in conjunction with an additional handle, which is installed on impact drills, designed for long-term use in construction.

To help the carpenter

Prefix for milling turns an ordinary drill into a small-sized home machine, which is used in the repair of furniture. By turning on the low revs and holding the device in a special mount, you can make a selection in the right place or pierce the side groove.

Greater accuracy of surface treatment is not expected, but this is not necessary, for example, when installing piano loops - nothing is visible under them anyway.

Original nozzles

Sometimes it is necessary to drill holes in a very inaccessible place where the standard product does not fit due to its size, then use the original nozzles for drilling at different angles. The angle drive is ideal for use with any model of electric or cordless tool, because it has its own chuck, where the drills are clamped, and the torque is transmitted through the gearbox and shank, which is fixed in the main drill.

Such a device can be used not only when drilling, but also when tightening fasteners (screws, screws and screws), cleaning and polishing hard-to-reach places - we clamp the right bit or nozzle and perform the planned amount of work.

There are quite unusual applications that are used for electric drills - pumps. They can not work for a long time - with their help, you can quickly pump out the viscous remnants of paint from the barrel or ground water that has leaked into the cellar. Their performance is not very large, but you have nowhere to hurry. The body of the nozzles is made of durable plastic, the life of the small, but the price is low.

Racks

To accurately drill the necessary holes in various materials use special racks or guides consoles, which can be purchased in stores - they provide vertical movement of the drill, clamped in a special basket.Compactness, smoothness and accurate metric scale make them attractive for equipment of a small workshop, where a home craftsman will be able to precisely drill any holes, even in objects of circular cross section.

A small vice with clamped workpiece can be installed anywhere in the bed and firmly secured, thanks to the grooves cut in the base.

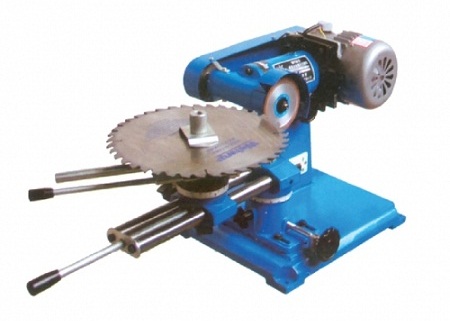

Unique sharpened

On the drill for sharpening various tools, you can install special nozzles - it turns into mini sharpenedwhich can be used for sharpening drills, circular saw blades, chisels, knives and various types of planers. The value of these consoles is that they help to significantly save the family budget - the services of professional grinders of a similar tool, especially drills, are at a rather high price level.

The device of such nozzles allows you to work at different angles, and a cylindrical nozzle is used for sharpening drills. To sharpen other tools, special devices are used.

The photo shows the original nozzle for sharpening drills of any diameter and machine straightening circular saws.Installation of various nozzles on the drill is not particularly difficult.

Woodworking

Drill can be used not only for drilling and as a mixer, it is necessary to attach a special device to it - it turns into an original machine or jigsaw on a tree.

Lathe

What a home craftsman does not dream of his own woodworking mini-machine, but such devices are very expensive. There is a way out - these are unique attachments to a hand drill, which have a different design and an appropriate tool for working. These devices are not suitable for mass production of carved balusters and legs of coffee tables, but it would be advisable to use them in the country or country house.

The design of the lathe for the drill is very simple and compact, any user will be able to work - all that is needed is desire and slowness of action.

Jigsaw

It is hard to believe that a jigsaw can be made from an electric drill, by its construction it is quite different tools, but nothing is impossible in the world. Found a designer who invented the nozzle that converts the rotation of the drill into reciprocating saws on the tree.Now it is possible to cut boards of various thicknesses with the help of a drill, and for lovers of filigree woodworking - to cut out unique patterns from multilayered plywood using a jigsaw.

Iron sheet cutting

There are special nozzles on the drill for cutting - they were developed by leading engineers of companies producing various models of drills to facilitate the work with roofing material. Work on the roof It does not allow to take a lot of tools with them, and every time it is troublesome to descend on stationary equipment to trim the excess on stationary equipment.

With the help of an ordinary drill on batteries, you can cut off the required strip from the steel sheet directly on the spot or remove excess. With this nozzle for metal cutting, you can cut a metal mesh, thick plastic, cut out a whole sheet of the required configuration and part size.

The unique device cuts metal freely, while you can change the angle of the instrument and work not only at a right angle of 90 degrees, as ordinary metal scissors do.

On the basis of an electric or cordless drill in a small workshop you can make many useful tools with your own hands, for example:

- device for the drill in the form of a drilling machine;

- grinding machine;

- sharpened for knives and scissors.

Some craftsmen even make homemade drills of various capacities, which are used during the repair of household appliances, where it would be difficult to use a standard drill.

To drill the desired diameter hole in the workpiece or parts, there are special nozzles-templates that facilitate the work of a little unsure of their users - call them the jig. There are already standard sizes for various operations, there are professional templates made of steel, and for domestic use - from plastic or durable plastic.

/rating_off.png)