Varieties of mechanical hand drills

In our century of domination of various electric tools the mechanical drill is forgotten by all. Only a few of the masters of the old generation have kept rarities: in their workshops in the place of honor are hand-held devices of different models - greetings from the last century from the USSR. However, mechanical hand drills remain the most economical, practical and autonomous, compared with their descendants - electric models. You can work with a hand drill everywhere, even on a deaf hunting zaimka in the taiga, they need only skilled hands.

Content

The advantages of the machine tool

The main advantage of a hand drill is a simple device and a unique reliability of all parts made of very durable metals. Break something in this design is quite difficult, and it differs from the electrical model. There are many examples when such a product regularly serves for several generations of craftsmen.

It is a hand drill that perfectly copes with drilling in such delicate materials as drywall, fiberboard, brittle plastic, various types of wood and plywood. She can work on the roof or attic, because she does not require an electrical connection.

Excellent performance of this simple tool when tightening and turning out different threaded fasteners: screws, screws, screws - you just need to insert into the cartridge the corresponding bit. Plus devices can be called and low cost such a tool: no more than 1 thousand rubles, so that a hand drill is available to all segments of the population.

In medicine, a hand drill is widely used for specific treatment of bones and the installation of needles in them - the DR-2 model.

Types of designs

Experts divide the mechanical drill into two main types.

- Product with one rotation speed.

- Manual two-speed design with a special gearbox.

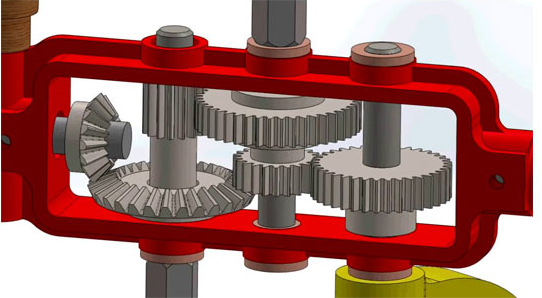

Developers from different countries for a long time struggled with the problem: how to make it so that a simple hand drill could work at two speeds. For these purposes was invented two-step multiplier - the original design of the gearbox, which has in its assets a set of gears arranged on different axes in a single package.

To switch the drilling speed, you need to move the rotation knob to the other side. The gear ratio of the gearbox increases or decreases, respectively, and the number of revolutions of the cartridge changes in one scroll of the handle.

Models are produced where it is not necessary to reset the handle - the speed switches as a result of the longitudinal displacement of the axis of rotation of the handle.

The main difference of this model is the gearbox: it is closed type and is located in a special case, but, as in the first version, it is easily disassembled, all parts are accessible for cleaning and lubrication.

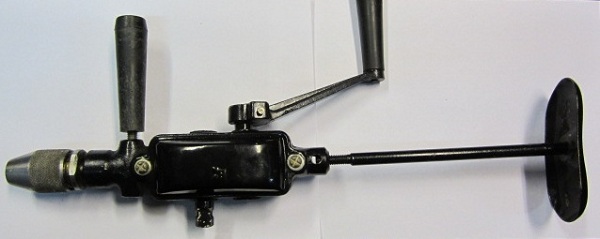

The figure below shows the two-handed version of the hand drill:

Ancient progenitor - brace

Kolovorot is an analogue of a hand drill, which our far ancestors invented, is not outdated, it is too early to write it off.It can be useful to unscrew the "recalcitrant" screw or stuck screw. To do this, you need only to sacrifice the old screwdriver and apply muscular strength.

The design of the limb is extremely simple. It consists of two parts: the frame and the simplest device for fastening the drill (chuck). In the figure below you can see a fine example of the Soviet industry for domestic use. The frame is specially bent and forms an incomplete rectangle, on the side is rotary knobwith the help of which smooth rotation of the whole structure around the axis is carried out.

The upper hemispherical handle is affected by pressure, it also rotates freely, without interfering with drilling. By the same principle drill for drilling holes in winter fishing or indentations for seedlings in the garden plot, which can be designed with your own hands. How to make a simple brace can be found, for example, from this video:

Home crafts

At home, you can make a simple hand-held drill with your own hands from improvised means, designs and variations a great variety.We will give a few links to the video, which details how to make the original design.

- Drill on the basis of mini-motors:

- A mini-machine where dental burs are inserted to make inscriptions on various surfaces at home:

- Mini-machine for grinding jewelry based on the old drill:

.

Safety and nuances when choosing

Before you make a choice of a mechanical drill, special attention should be paid to the workmanship of all visible parts, smooth course of rotation of the cartridge, convenience handles. Burrs, sharp edges and edges are not allowed on the body, the gears inside the gearbox should rotate without extraneous noise.

Mechanical simple hand drill does not require special skills to use. But there are safety requirements that are designed to minimize the possibility of injury to the worker and breakage of the tool.

- Any piece to be drilled should firmly fixed. If you hold it with your hands, it can break out and cause injury.

- Do not touch the drill with your hands - as a result of friction, it warms up a lot, especially in cases when the metal is drilled.

- When drilling at high speed necessary take breaksso that the drill bit cools or coolant is applied to it.

- Protect your hands with gloves, and your eyes with glasses, because small drilling waste can cause injury, although the speed is not so great.

Security measures have been developed over many years based on an analysis of accidents during work and take into account the most negative cases from practice.

/rating_off.png)