Homemade Circular Saw

Circular saw is a specialized equipment that is used for sawing wood, laminate, some varieties of wall panels, sheet materials, such as plywood, OSB, chipboard. When carrying out a number of construction and repair works and carpentry operations, the presence of a stationary-type sawing installation can significantly reduce the time and improve the quality of the result. If it is not possible to purchase a factory-made model, you can assemble a circular saw with your own hands. For its self-production will require the most common tools and skills to work with them. The more materials and parts are available, the cheaper the project will cost.

Content

The design of the stationary circular machine

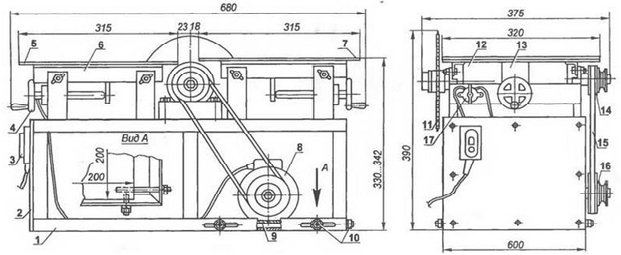

The stationary circular saw is intended for performance of rather large volumes of works. The design of the implemented variant in two types is presented in the diagram below. It also indicates basic installation dimensionsfrom which it is recommended to make a start at independent assembly.

In the drawing, the numbers correspond to the following structural elements of home-made equipment:

- 1 - frame (bed);

- 2 - side panel;

- 3 - starting device;

- 4 - the mechanism for adjusting the height of the table, 13 - its stops;

- 5, 6 and 7 - the two halves of the sawing table with the base;

- 8 - electric motor;

- 9 - platform for the installation of the motor;

- 10 - studs (M10);

- 11 - saw;

- 12 - shaft;

- 14 and 16, respectively driven and driven pulleys;

- 15 - belt;

- 17 - the switch.

It is better to place the trigger in a visible place on the panel (of dielectric material) so that access to it is free. It is also recommended to equip the machine emergency switch. It is convenient when it will be large.

Focusing on their own needs, you can improve the unit by making it with a jointer or plane. To do this, it is enough to fix the drum with knives on the existing shaft, and in the table make a slot for it of the appropriate size. This will allow to expand the functionality of the created installation: to cut timber on it, to remove the chamfer and to choose a quarter of the wooden blanks.

If regular joinery operations are planned on home-made equipment, it is recommended to equip it coordinate table with several guides. They need to be fixed at different angles. For the organization of productive work, you should also provide the ability to control the speed of the electric motor and quickly replace discs if necessary.

Selection of materials and parts

When creating a home-made circular saw, it is necessary to maintain an optimal balance between its functionality, safety during operation and manufacturing costs. To achieve this, you should choose materials and parts with the desired characteristics. To reduce costs, you need to build on the old or unused equipment that is available.

Materials for the manufacture of bed with a table

For the manufacture of the frame (frame) can be used channel or metal corners (enough size from 25 × 25 mm to 50 × 50 mm). If these materials are not available, then the most economical option is to purchase them at the scrap metal collection point. On the legs of the machine will go water or profile pipes made of metal.

Assembling the frame, it is also required to stiffen the structure in the corners to weld the struts. To facilitate the movement of the machine, you can equip it with durable wheels (with a metal rim), equipped with latches.It should be borne in mind that the more massively the created aggregate, the more stable it must be in order to avoid injury.

The bed of the metal pipe

The main requirements for the table for circulars: resistance to mechanical stress (vibration, shock), the ability to withstand without deflection billet weighing more than 50 kg and surface smoothness. These properties are characterized by sheets of the following materials:

- become;

- duralumin;

- silumin;

- PCB;

- moisture resistant plywood;

- organic glass.

If use moisture proof plywoodthen it should be pre-beat zinc-coated tin. It is not recommended to use chipboard or OSB due to the instability of these sheet materials to vibration effects.

Important! The strength of the table is of great practical importance. When it is cracked or skewed due to deflection, the disk may jam. This can lead not only to damage the workpiece, but also to injury.

To carry out various works (for example, spreading logs on boards) you need to equip the table side stop. It performs the same functionas a tire for a circular saw of the manual type: ensures smooth sawing of lumber. Moreover, its use allows to obtain blanks of different sizes.

Guide stop must be strictly parallel to the disk to avoid jamming of the latter. It can be made from a wooden bar or a metal corner. In the first case, only hardwood should be used. In order to be able to adjust the working clearance, the support must be removable. It can be fixed with the help of clamps or in special grooves (bolts) made parallel to each other on the working surface of the table top.

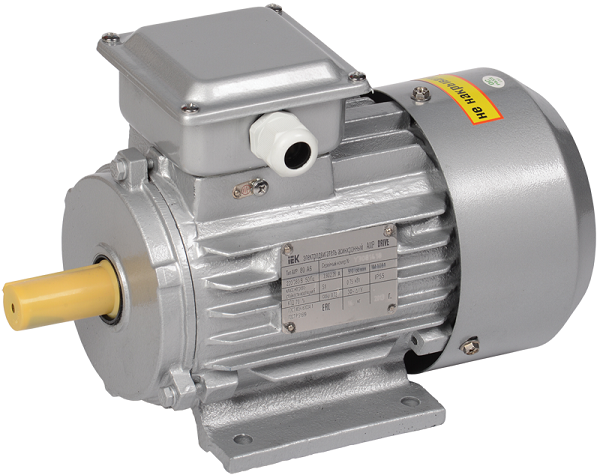

Selection of engine and starting equipment

As a drive for the considered version of a homemade circular machine, the easiest way to use single phase electric motor. Its power is required to pick up taking into account the forthcoming load. Indirectly, you can navigate the diameter of the installed disk:

- if it is 350 mm, then for normal operation of the unit a 1000 W electric motor is needed;

- for a disc with a diameter of 170 mm, an engine of 500 watts is sufficient.

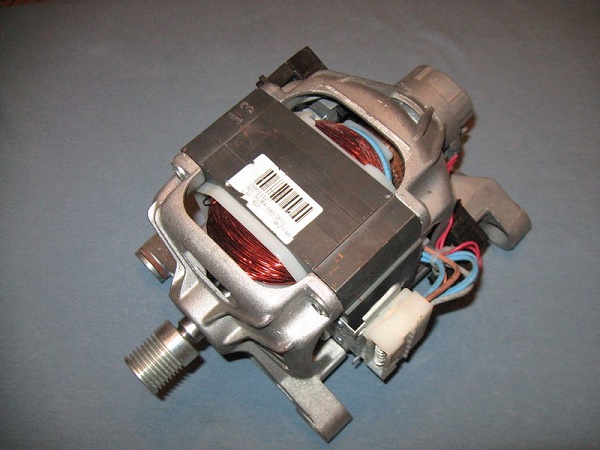

In the latter case, it is possible to manufacture a drive mechanism from the engine of a washing machine. He is able to work for a long time with an average level of load.For discs with a diameter of 350 mm, an electric motor from an industrial ventilation unit is suitable. It should be fastened tightly to ensure normal engagement of the belt drive. For this reason, it will not be possible to reduce the level of vibrations by installing the motor on the shock absorbers: it will constantly fluctuate.

You can also equip homemade equipment three phase electric motor (380 V) suitable power. In order to run it from the mains with a voltage of 220 V, it will be necessary to additionally install a working (phase-shifting) and starting capacitors in the electrical circuit. It should also be borne in mind that the engine power in this case will be less than the nominal value indicated on its plate or in the passport.

Starting equipment should be selected on the basis of the power of the motor, which will depend on the maximum current in the circuit. A good option is to use the start button in conjunction with thermal protection - this will prevent the motor from burning out the windings if the current increases when the disk is jammed. It is better to install the protection in a separate electrical panel attached to the side panel of the machine from the convenient side.

All connections must be well insulated so that the wires do not close to the frame of a homemade circular electric saw. The on and off buttons should be pressed without any effort. Due to the frequent storage of equipment on the street, the electrical part is necessary well. protect from wet. The simplest thing is to cover the installation with an oilcloth or similar non-waterproof material.

Transmission, shaft and disc

For transfer of rotation from an electric motor to a disk, the best option is to use V-belt together with pulleys from the car engine. Gears are not recommended for safety reasons. This is due to the fact that if the disk is jammed, the belt will simply slip, and the gear transmission, due to its rigidity, can cause the failure of the entire drive unit.

Shaft manufacturing it is better to entrust a specialist by ordering it from a professional turner.Especially when it is planned to make a circular power saw more functional, equipping it, for example, with a plane. But the simplest option is to buy ready-made parts of factory production. Her sample is presented in the photo below.

Together with the shaft it is recommended to use self-aligning ball-type bearings. Fasteners for them are suitable from the car hub kit. In this case, the bearings should be well protected from dust.

Disc for circular machine it is easier to buy ready-made than to make it from a sheet of tool steel. The problem is balancing. The unbalance of the saw during the operation of the equipment leads to its rapid failure and reduces the level of safety of the workflow. If there is a circular saw on a tree, then it is possible to remove a saw disk from it.

It is necessary that the diameter of the disk corresponds to the corresponding parameter of sawn timber: for example, for 100 mm of logs you will need to use a saw about 350 mm in size. This is due to the fact that the disk should not protrude more than a third of its diameter above the working surface of the table.

Ignoring this requirement not only leads to a deterioration in the quality of sawing the workpieces, but also increases the possibility of injury.

Algorithm assembly homemade circular saw

The assembly of the woodworking machine according to the drawing above is performed in the following sequence:

- from the corners make a rectangular frame;

- Four legs are welded to it at the corners of the desired height;

- at a height of about 200 mm from their lower edge, they make a harness from the corners;

- shaft mounted on the upper frame;

- they fix a driven pulley on one side of it and a disk on the other;

- make and attach a table with a lifting mechanism to the bed;

- on the bottom frame make the area of the corners or sheet metal under the electric motor;

- the drive pulley is fixed on the motor shaft;

- put the belt on the pulleys;

- on the side panel of the unit are mounted on / off buttons and electrical panel;

- using wires of a suitable cross-section connect elements of the electrical circuit of the equipment (engine, buttons, protection);

- supply power to the machine from a fixed network.

The final stage is performance check of the assembled equipment. First you need to make sure that all moving parts are free to rotate: to do this, simply twist the drive pulley with your hand. Then you can start the unit in test mode. If a strong vibration is detected, it will be necessary to check the reliability of the bolted connections and the fixation of the disk.

You can make a circular saw with a table consisting of two halves or solid. In the latter case, it will need to cut a rectangular slot under the disk. The design of the machine with a table consisting of two halves is shown in the video below. Also in this video the device of the lifting mechanism to these parts is demonstrated.

Important! To prevent the saw from jamming due to the joining of the fragments of the sawn billet, it is recommended to install a riving knife. It should be placed about 3 mm behind the disc.

Recommendations for simplifying the assembly process

To regulate the belt tension, the motor must be installed so that it can be moved. The easiest way to achieve this is to create cuts larger than what is required under the mounting bolts of the motor.In this case, the expansion of the holes must be carried out in the direction of the belt tension.

If you completely follow the drawing, you will need to make a more complex belt tensioning mechanism. The process will be carried out by tightening the platform with an electric motor with the help of studs and fixing it with locking bolts in the desired position (in the drawing these structural elements are marked with the number 10).

The entire design and assembly process can be greatly simplified by making circular saw circular saw. In this case, the need to install a number of parts (engine, disc, shaft, belt, starter) disappears. But the possibilities of the created model will be limited by the power of the used tool.

Homemade Circular in any case must be grounded. Also, in addition, it is recommended to install a safety device or a differential automatic device in the shield. These measures will protect against electric shock if the machine body is energized, for example, due to breakdown of the insulation of the wires. Components for the electrical part of the circular machine is better to choose so that they are suitable for repair and easy to maintain.Free access to equipment nodes will help to easily replace broken parts.

/rating_off.png)