Home-made power-saw bench and circular saws from electric saws

Own power-sawmill is a profitable device, since wood is one of the most popular building materials. There are two options to get a sawmill: make yourself or buy in the store. Of course, the second option is simpler, but the first one has more advantages. First and foremost, a homemade chain saw is more cheap productin addition, such a device will fully comply with the requirements of the owner.

Below will be presented two versions of home-made saws: a power-saw bench power saw and a circular saw from a manual circular saw. For the manufacture of the first will have to make some purchases, as well as stock up on a welding machine, the second option is quite possible to make from materials that surely can be found in any owner in the garage or on the site.

Content

Types of sawmills

Sawmills, which are sold in the store - are excellent productive devices with great functionality, designed for large volumes of wood. Such a tool can pay off in 2-3 months, but it is not advisable if the use is solely for domestic purposes. In this case, it can be made with your own hands from a small electric saw.

Currently, there are three types of sawmills on the tool market:

- disk;

- tape

- tire.

Circular saws - one of the most common in the economy. Their disadvantage is the high cost of high-quality discs, as well as a relatively large amount of waste. Band saws are the most economical, they are not afraid of bad weather, they leave little waste, but at the same time they have a complex structure, which makes them making them at home very difficult task. The simplest version of the saws made of electric saws is a tire, they are distinguished by an elementary device, and can also process large volumes of wood of any thickness.

Self-manufacturing tire saw

In order to make a sawmill on your own, you will need drawings and certain calculations. The manufacturing process is not particularly complex, the only thing is the availability of all necessary resources. Naturally, the self-made sawmill will be inferior in characteristics to factory products. but for the manufacture of beams and planks great fit.

For the manufacture of tire saws will require certain materials:

- metal rails;

- metal tubes with different diameters;

- electric motor;

- tire from the chainsaw;

- leading sprocket (also suitable for chainsaws).

As an electric motor, you can use any engine, for example, from a semi-professional electric saw, from an old grinder, or you can buy it specially.

If the choice falls on the purchase option, then a 5.5-kW three-phase electric motor is ideal for domestic needs.

Cutting assembly

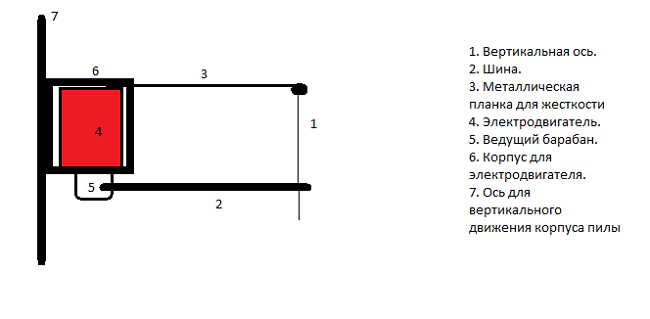

The cutting part is represented by a tire and an electric motor connected to each other. The whole structure is placed in a metal frame, which is mounted on a vertical, solid axis. In other words, the frame in which the saw is enclosed,will be able to move vertically inside another frame. This movement will occur at the expense of the guide axis.

The first step will be frame makingin which the tire will be installed. The frame has the shape of a rectangle. On one side of the tire, it is attached to the vertical axis, which provides rotation.

The asterisk that drives the tire has a central hole. In it you need to insert the axis of a strong alloy, which has high strength. Great for low carbon steel. The axis is opposed to horizontal movement of the tire, that is, the tire itself has a horizontal position in space, and the axis is vertical. Bearings are fitted on the axle on both sides closely to the tire - this helps to avoid vertical displacement of the cutting part. After that, sleeves that grip the bearings are put on top.

The upper part of the axis is attached to the metal profile. The opposite part of the profile is welded to the frame in which the motor is installed. Thus, a rectangle is formed as follows: the lower part is a tire, on both sides of it is an axis and an electric motor, and the upper part is a slat.

This design does not allow the tire during operation to give a backlash.

Electric motor and driving drum are attached in the opposite part of the axis. To attach them to the tire, you will need the remaining parts from the saw. The electric motor is mounted on a rigid case. It should take into account the large vibration, which means that the basis for the engine must be very rigid. From the side of the engine, a metal axis or a rigid profile is welded. It is due to him that the entire cutting structure will move vertically in order to ensure that the log is cut in the right place.

Carrying body with saw to base

The next step is to transfer the entire structure to the main frame, which has the shape of a parallelepiped. This frame mounted on rollersthat will move along the rails and saw the log. The sides are a welded frame of thick metal. From above, they are fastened together. In other words, the front view will resemble the letter P, mounted on rails.

The distance between the side posts is 1-1.5 meters and is calculated based on the length of the tire: it should be slightly larger.The side racks themselves are of such width that it is possible to install a construction with a cutting base inside. If this design is 60 cm wide, then the width of the side faces should be the same. This is done with the expectation that a saw will be installed inside one of the racks. The axis on which it moves, is attached at the top and bottom inside the side frame.

Thus, the vertical movement is provided by the axis. Movement horizontally occurs with the help of rollers that roll on rails.

Production of circular saws from manual disc

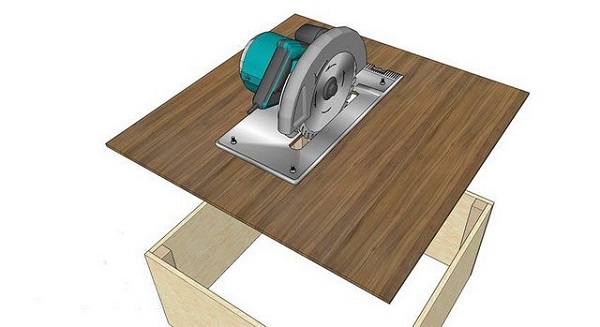

For a home craftsman, having a circular saw at home is a matter of vital importance. Make it quite possible with your own hands. The easiest option to make a circular saw is to use a hand-held circular saw. For the manufacture of the machine design does not need to alter the existing saw. Enough make a table for her. Obviously, the saw will be fixed under the table top, and the disk through a special hole is located above it.

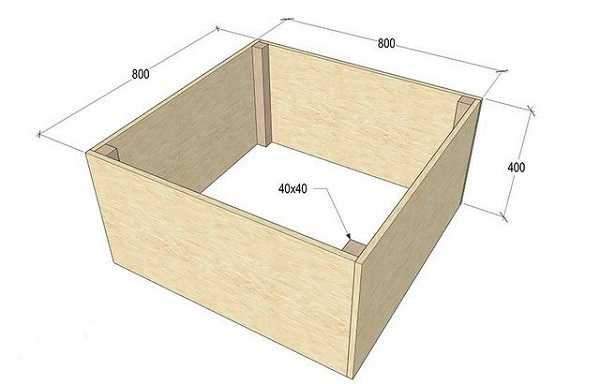

For the manufacture of the table will need wooden bars 40 * 40 and plywood. A square base is made with a side length of 80 cm and a height of 40 cm.

A square sheet of plywood is taken as a tabletop, it is best to use varnished or laminated - it provides smoothness and easy sliding.. In the central part is cut for the disk. The corners are pre-drilled holes for attaching the tabletop to the table.

Below to the table top mounted circular saw. The easiest way to do this is bolted. Hats must be carefully drowned in the surface.

To turn on the saw, you need to fix the power button on it, and plug the power plug into the outlet that will be connected to the start button.

For ease of use, you can attach a metal corner on one side, which will serve longitudinal stop. To move it, you can make cuts at right angles to the disk, and move the movement, loosening and tightening the bolts that fix this stop.

An electric circular saw is a simple and inexpensive option for home use. Of course, with the installation of the tool, the thickness of the tabletop will steal a little from the disk, but in general, this option is quite enough for domestic needs.

/rating_off.png)