How to use the electric planer

Electrical plane, available from the mid-20th century, became indispensable for craftsmen processing lumber. Their popularity is due to the presence of a number of advantages over conventional manual planers. When using power tools, the laboriousness of the process is reduced, labor productivity increases, and the quality of workpiece processing is also improved. In addition to planing using a tool, specialists perform a quarter cut, chamfering and other operations. To get a high-quality result, you need to know how to work correctly with an electric planer and to observe safety rules.

Content

Preparation for work with an electric plane and the rules for its installation

Acquired recently or for the first time in practice electric planers need to be checked.

Without preparation, it is not recommended to start operating the mechanism, because it can lead to its breakage or damage to wooden blanks.

You should first read operating instructions. Next, conduct preliminary training, checking:

- the position of the front of the sole;

- degree of freedom of rotation of the working drum with cutting elements fixed on it;

- the presence of various damage to the plug, power cord, housing;

- freedom of movement of the power button;

- the correct location of the knives.

The performance and equipment of the electroplane must be checked at the time of purchase. Rotation of the drum is checked by moving it by hand. The operation of the button - by clicking on it. The integrity of the unit is determined visually.When no defects are detected, it is possible to carry out trial switching on of the equipment.

Before planing with an electric planer or performing other operations with it, it is recommended to practice it beforehand on processing on unnecessary planks or bars. This will allow "to fill the hand" and adapt to the technique in order to get an acceptable result in the absence of the necessary practical experience.

If the switched on tool starts to vibrate or when working, the quality of the processing of the boards is poor (waves and tears appear on the surface of the wood), you should sharpen or replace the knives on the drum.

Setting the correct position of the front of the plate

It is recommended to start electroplaning adjustment by adjusting the position of the front part of the plate with the plug turned off. For this you will need use the ruler or a suitable size piece of ordinary glass. All actions are performed in this sequence.

- The front (movable) part of the sole with the help of a special adjustment knob is set to a position that provides the minimum depth when planing.

- Install the power tool on an even workbench or desktop upside down.

- The drum is scrolled so that one of the knives is located above its axis.

- On the sole put a ruler or glass: while they must lie in the same plane.

When the pad on the plate is located with a slope, then eliminate this defect as follows:

- remove the adjusting handle and the front of the sole;

- clear the opened cavity of shaving and dust;

- lubricate the mechanism;

- put the plate in its place;

- set the handle;

- check the position of the sole with a ruler.

Adjustment is considered complete when the glass or ruler is located in the same plane with the sole.

Checking the installation of knives

The installation of the blades is checked using metal ruler. To do this, it is applied to the edge of the plate. Then look, whether the line of an edge located on a drum touches. When the knives are not in contact with the ends of the lining, proceed to their regulation. Using the key (hex), complete with power tools, loosen the blade on the drum. Then, the cutting edge of the knife is set parallel to the sole so that it protrudes about 0.5 mm in flat models and from 1 mm (or more) in rounded ones.

The considered method regulates the position of the blades in models with both one knife and two or three. After the regulatory adjustment is completed, they will be installed in the desired position.

It is necessary to take into account that the depth of planing and the ease of the tool travel depend on the protrusion of the knife above the sole.

When setting the correct position of the blades, they should not touch the sole when the drum rotates.

Possible working positions electroplane

Some models of electric planers contain support stand. This makes it possible to perform work using this device in two ways:

- placing it in a stationary position, when the power tool is fixed (rigidly) to the workbench or table;

- using an electric plane as a portable equipment.

In the latter case, the movement of the tool occurs along the treated surface. So convenient to handle long wooden blanks.

Electrical plane with support-stand included

A rigidly fixed tool is, in essence, planer The wooden blank is driven over it, pressing it with enough force.In this case, it is convenient to perform work operations with the help of a partner. It is possible to work with lumber of small length and alone.

The easiest way to prepare an electroplane for work is to turn to specialists for help. service center. Self-tuning of the instrument should be carried out according to the recommendations set out in the manufacturer’s instructions.

Electroplane various types of work

With the help of electric planers you can perform various operations:

- plan a wide or narrow plank, as well as other wooden blanks;

- choose quarters;

- clean the chamfer.

Before performing work should be selected good quality lumber:

- no knots;

- well dried

- without cavities filled with resin, chips and cracks (longitudinal or transverse);

- with a smooth surface that does not contain cavities or protrusions;

- in the board or in the timber there should be no metallic inclusions: nails, screws, bolts, brackets, screws, brackets and others.

With a portable method of using an electroplaner, the workpiece is securely fixed on a solid surface. To do this, install at least 2 stops, but it is better to arrange them on all sides of the part. Also provide free movement of the power cord so that it does not cling. The safety of the operator depends in part on this.

Quarter sample using electric planer

Quarter sampling (fold removal) is one of the operations performed by electroplaning. To perform it is required installation of two stops:

- the first (upper) controlling the movement of the tool on the workpiece in the right direction;

- second (side), which determines the depth of the sample quarter.

The stops are set to the required dimensions, following the instructions of the operating instructions for the product used. In this case, the measurement of distances is performed, focusing on the cutting edge of the blade occupying the upper position.

You can choose a quarter in two ways:

- moving the electric plane on the workpiece;

- moving the processed wooden part on a homemade machine.

In any case, the movement of the power tool or workpiece must be at the same speed (smooth).

The removal of the seam in the first case is carried out in several passes, and act in this way as follows.

- On the surface of a well-fixed workpiece with a marker or pencil put marking lines that define the depth with a quarter width.

- Include electric plane.

- After a set of full revolutions of the drum, bring the tool to the workpiece. The movement begins with a slight pressure on the front of the working unit, leveling the force after the sole is completely on the surface of the part and increasing it at the end.

- Perform passes to achieve the desired sample size.

Quarter Sample

For marking on long workpieces it is convenient to use a marking cord.

The second option (stationary) is more productive if you need to perform significant in terms of volume of work.. Work with the work slowly. After its leading edge goes beyond the drum, it is intercepted by the second hand, distributing the effort evenly over the part.

Quarter sampling is a rather complicated operation that requires the presence of such skills. Therefore, such errors may occur:

- bevel angle caused by poor fixation of the workpiece;

- "Ladder", which is the result of improper installation or adjustment of the position of the knives;

- curve groove due to the initial curvature of the side face of the workpiece.

Uneven pressure on the plane and its collapsing in any direction when removing the fold leads to the emergence of bumps, roughness, grooves. Therefore, you should constantly monitor it, what comes with experience.

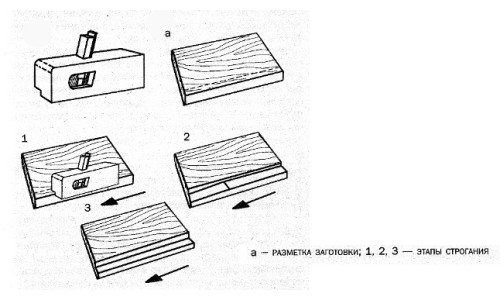

Planing sawn wood surface

Planing wooden blanks is the main function of the electric planer. When performing this operation, you should follow these recommendations.

- When processing blanks by planing, it is required to carry out movement with an electric plane from the edge along the fibers (with a portable method of using the tool) or move the part on the machine, placing it correctly.

- If the wooden structure consists of several elements, for example, it is a prefabricated shield, then the movement of the power tool is performed diagonally (at an angle of 45 degrees) to the fibers, exposing a small depth of planing.

- It is necessary to move the plane, evenly distributing the effort and observing that no chips fall under its sole (it must be removed in a timely manner).

- The ends of the timber or planks are rarely treated, pre-setting the minimum depth of processing and removing the chamfer on one side.

- In order to maximize the quality of the detail, initially it is taken of greater length, after planing, cutting off the ends.

- Each facet of the workpiece is processed separately.

- When performing work on the machine part serves, resting in the side stop and intercepting while in the hands.

- Wide blanks are cut in several passes.

- Planing depth exhibit, focusing on the degree of roughness of the surface of the lumber.

- The power tool sole should always be parallel to the work surface.

- In order not to overload the electric motor, hard wood planes are planed with a small depth of several visits.

When rough planing allowed to move the tool across the grain of the wood. To minimize the appearance of defects, the plane must be moved slowly, evenly distributing the work force. It is quite difficult to plan panel structures on improvised stationary equipment. In such cases, it is better to use a handheld device.

The ends are planed to reach the border of the removed chamfer. That the processed preparation was no lanes, make additional passes a plane on its surface, setting the knives to the minimum depth.

If a vibration or other manifestations that are uncharacteristic for normal operation of the planer occur, you should turn it off and deal with the cause of the malfunction.

How to plan the boards shown in the video:

Chamfering at blanks

Chamfering refers to the additional capabilities of electroplanes. For this purpose is intended V-shaped groove on their sole. To make a chamfering, the tool set this notch at the corner of the workpiece. Then the plane is moved along the part, maintaining the desired slope. After the first pass, the rest can be performed normally without using a groove. At the same time, the bevel angle is set with the help of a side stop, which during the whole operation must always fit tightly to the workpiece.

During chamfering, the power tool should be kept flat, without tilting, so that it does not turn out to be rounded at the end.

For the qualitative performance of any of the considered operations with an electric planer, experience and skills are necessary.

Safety rules when working with electroplane

The electric plane is a device, during work with which it is necessary to observe safety precautions.The main damaging (traumatic) factors are:

- rotating at high speed drum instrument with knives located on it;

- electric current flowing through the device.

To work safely with the Interskol electroplane or any other model, you must observe the following rules.

- The workplace must be kept clean, it must be well lit.

- Do not use power tools in areas where there is significant probability of fires or explosions due to the presence of flammable liquids, dust or gas.

- It is impossible to allow unauthorized persons or children to the working tool, and it should be kept in a place inaccessible to them.

- It is forbidden to be distracted while working on other matters, as this may cause a loss of control over the tool.

- Should not be allowed water ingress on the used power tool, as well as carry it by holding the cord.

- If an extension cord is used, it must comply with the load and also have a complete insulation.

- The power cable should be away from highly heated objects and sources of temperature, from moving parts of various mechanisms, as well as from sharp edges and different liquids (especially oil).

- It is forbidden for the body to come into contact with surfaces that are grounded (for example, radiators and heating pipes) while working with a plane.

- In a state of alcoholic or narcotic intoxication, as well as under the influence of drugs or when fatigued, the use of power tools is prohibited.

- Should be carried out regularly preventive technology service devices.

- Do not touch the working drum with your hands.

Connecting the power tool through the RCD (protective cutout device) in any case increases the safety of work with the equipment. Protection should be selected according to the magnitude of the load.

Conclusion

The operation of the electric planer begins with the proper preparation of his work. The planing, quartering, or chamfering operations are performed differently. It should be remembered that the use of a faulty power tool is prohibited. When repairing it is recommended to install only original spare parts. Troubleshooting should be entrusted to service center specialists in the absence of the necessary skills.Ignoring the considered safety rules can lead to injuries of varying severity, electric shock and even fire.

/rating_off.png)