Adjustment, replacement and sharpening of electric cutting knives

Electric planers are an indispensable tool for modern carpenters, carpenters, as well as all professionals involved in the processing of lumber. Their prevalence is due to practical efficiency and the presence of significant advantages in this equipment compared to hand-made analogs. To fully utilize the potential of the device, the electroplaning knives need to be pre-adjusted before processing the wood. Also the blades should be sharp. This will allow, together with the correct setting of their position, to process significant volumes of boards or bars without any special problems and efforts on the part of the user.

Content

Types of electric cutting knives

Knives on the electric planer are a consumable item. With their help, processing of wooden surfaces is provided.

Often, the knives come with 2 power tools.

Knives for electroplanes are classified according to the following criteria:

- reusability;

- blade shape;

- the size of the knife;

- cost.

When buying an electric planer, in addition to checking its performance and configuration, one should pay attention to the quality of the knives mounted on the drum and their sharpening. Blades should be sharp, with a smooth edge that does not contain any bends or hollows. Should check and spare knives. The final quality of sawn timber processing depends on the proper selection of cutting tips.

Disposable knives

Knives for single use are made from hard steel based alloys in the form of sharp plates on both sides. Such cutting parts are not subject to sharpening. After the edge used is completely worn out,the blade is turned over and set on the drum with the other side. At the same time, the tool continues to work. If the second cutting edge is dull, the blade is simply thrown away.

Disposable knives are designed only for work that does not require high precision and quality of processing of workpieces. But they are convenient in practical use: when installing, they do not need to be precisely tuned and balanced.

In the form of disposable products are:

- straight;

- wavy;

- straight but rounded at the ends.

The first type of product has a straight cutting part. It is convenient to use such consumables in order to carry out processing of parts having a smaller width than the length of the installed blade, to select quarters. Wavy knives are used when necessary rough processing of lumber. With their help, you can give a wooden surface a different texture, for example, to imitate “aging”. Straight cutting edges, rounded at the edges, are good because they do not leave marks (grooves, steps) on the surface of the treated wood. This is a suitable option when you need to work. with wide wooden blanks.

Disposable blades have a longer service life, but can easily break if accidentally collided with a metal (for example, a nail, a bolt). They are the best option for attachments when working with hardwood blanks.

Reusable cutting nozzles

Products that are intended for reusable use, differ in their shape and size from disposable cutting nozzles. They are made using high quality steelthat provides ease and quality processing of wooden surfaces.

Using reusable knives, you can achieve such a degree of smoothness of the surface of the workpiece that grinding is not required. They have HSS marking (Fully High-Speed Steel, which translates as high-speed steel). Such blades are considered professional. Their installation is accompanied by high-precision balancing and adjustment. Sharpening must also be of excellent quality. In this case, tool high-speed steel can be sharpened so that it is very sharp.

It is more profitable to buy reusable cutting nozzles, because there is the possibility of sharpening them repeatedly.But to process hard wood (for example, larch or oak) products from high-speed steel do not allow.

On the working drums of most models of electric planers, you can install both disposable and reusable cutting nozzles. But there are also devices that can only be equipped with blades that are not designed for sharpening. For this reason, when buying an electroplane, it is recommended to give preference. universal power tools.

Size classification

Electroplaning knives can be standard or custom size. Products of the first type, called "plates", have a length of 82 mm, a width of 5.5 mm, and a thickness of 1.2 mm. Such cutting tips are suitable for most models of electric planers from foreign firms Makit, Skil, Bosch, Black & Dekker.

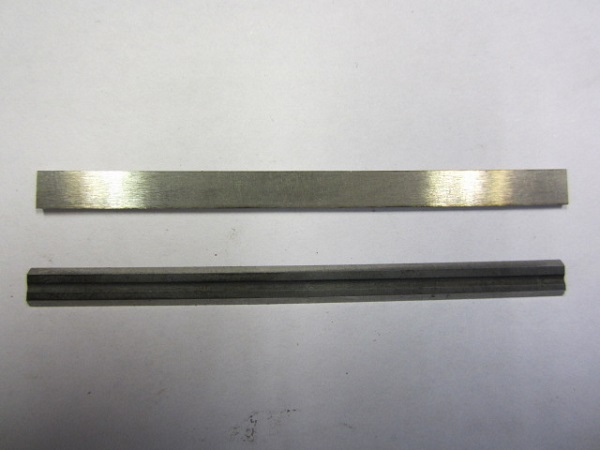

Knives straight for electroplanes Bosch, SKIL

Non-standard cutting nozzles with a greater width and thickness of the blades are typical for electric planes from the firms Baikal and Interskol. Because of their parameters, they are stronger and more qualitative than standard plates. At hit on metal such knives do not break. They can be sharpened with sandpaper.The width of the nozzles is about 1 cm. The length can be 82 mm, 102 mm, and for Rebir products it reaches 110 mm.

Knives direct for electroplane Rebir IE-5709

The price of the cutting nozzle depends on the manufacturer. Also this factor is often determined by the quality of the product. If you buy knives of well-known companies (for example, Bosch), you can count on their long service life.

Some models of electroplanes are completed with cutting nozzles of unusual shape and design. In order not to be mistaken with the dimensions, it is recommended to take an old blade with you for comparison before purchasing.

When you need to adjust or replace knives

Knives on the electric plane wear out over time. They need to be removed and sharpened or replaced at all, and then put back on the drum. Newly supplied cutting tips need to be adjusted to process the lumber as efficiently as possible. The blades of a new power tool also need to be preset. before use.

The following symptoms indicate that adjustment is necessary:

- sound change when processing blanks;

- tool vibration during operation;

- deterioration in the quality of sawn timber planing (the formation of waves, chips, grooves, protruding fibers and other defects);

- increase in effort spent on work.

The change in sound is not typical for all models. This symptom may also indicate a number of other problems.

If after performing the adjustment of the knife blades, the considered signs do not disappear, then you will need to make a more serious repair of the power tool.

Setting the correct position of the cutting nozzles is performed according to the following parameters:

- the height of the part of the blade that protrudes above the sole of the power tool;

- the size of the side protrusion of the knife, designed to select quarters.

With the help of the correct adjustment of the position of the knife blades on the drum, a high final quality of lumber processing is achieved.

How to adjust knives

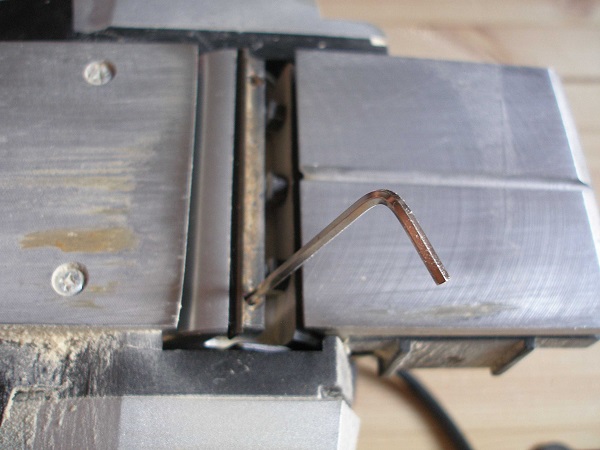

To adjust the knives on the drum alone does not constitute a special problem. To set the position of the tool blades before working, you will need:

- hex key that comes with a plane;

- metal ruler or piece of glass of suitable size.

Adjustment is made by performing all operations in this sequence.

- Turn the electric plane, placing it up drum on the table or workbench.

- If necessary, using solvent erased from the nozzles resin layers.

- Expose the position of the front of the sole to the position that provides the minimum depth of planing.

- Turn any blade, placing it in the slot between the plates.

- On the surface of the base plate put a ruler.

- If the cutting edge does not touch it, then the knife bar is raised to the desired level, loosening for this (slightly) the fixing bolts using a hexagon.

- After setting tighten the fasteners.

- The procedure is repeated with all nozzles, while setting gaps of the same size in order to prevent unbalance of the drum and the appearance of vibration of the power tool during operation.

- Turning the drum by hand, determine the ease of its rotation.

- Check the correctness of the settings on unnecessary workpiece.

In the considered sequence, the working position of the cutting edges is adjusted for models of electric planers with one, two or three knives.

It should be borne in mind that the working parts of straight lines in the form of knives should protrude by approximately 0.5 mm, and rounded parts - 1 mm or more.

If the adjustment is carried out correctly, the cutting edges on the drum should stand without distortions parallel to the sole of the power tool. A number of new models contain adjusting screwswhich you simply need to twist to set the knife plates in the desired position. To configure the tool, it must be disconnected from the mains, and in the wireless models, you should remove the battery. This will ensure that the power tool does not spontaneously turn on.

The algorithm for replacing knives on the electric planer

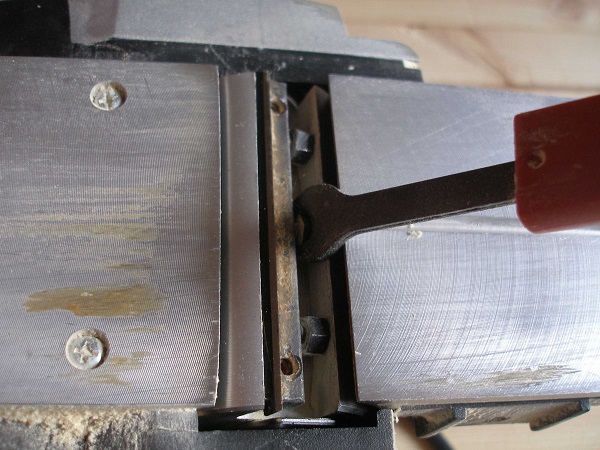

To remove the blades from the electroplane and replace them with new ones (or correctly sharpened), you will need a set of wrenches, as well as, in some cases, a screwdriver. It is not required to assemble and disassemble the electric plane completely, in order to change the working nozzles. Replacement is performed in the following sequence:

- turn the drum, exposing it in such a position to gain access to the bolts of the knives;

- loosen, but not completely, these bolted clamps;

- manually or using a flat screwdriver remove the working nozzle;

- with the remaining blades do the same;

- put new knives in the nest, fixing them with bolts;

- put them in the right position.

The main point is the need to put the blades exactly in the sockets and fix them securely so that they do not fall out during the operation of the tool. Due to the fact that different attachments of attachments for working nozzles may differ, it is recommended to first read the instruction manual for the equipment used.

On sale you can find knives, the blades of which are rotated. This is very convenient, because it is enough to simply flip the blunt edge, replacing it with a sharp one.

When mounted on an electric planer drum two cutting tips, you need to change both at once. This will prevent the occurrence of an imbalance, the consequence of which is a reduction in the quality of sawn timber processing and the failure of the electric planer.

Sharpening knives electroplane at home

With regular use of the electroplane for processing wooden surfaces (planing, quartering, chamfering),its cutting edges are blunted. If the knives are designed for reuse, they can be sharpened by yourself. Sharpening is carried out on the same principle as with manual planers. The differences are only in the number of cutting edges that you want to sharpen.

Use power tool with dull blades not for the following reasons:

- increases the load on the motor, resulting in accelerated wear;

- quality of processing of a surface of timber is significantly reduced.

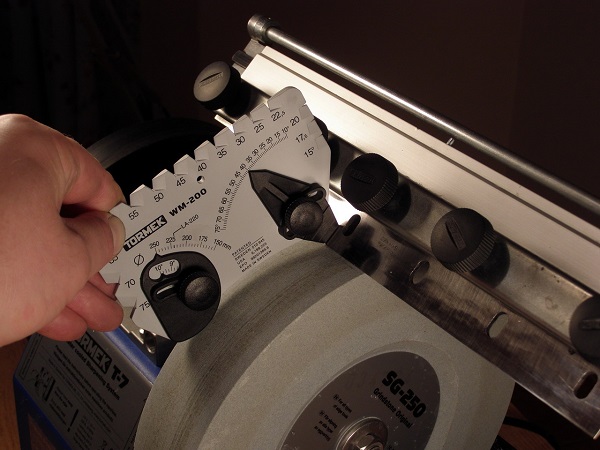

Properly sharpen the cutting edges of the nozzles will help experts service centers or special workshops. If you can not turn to professionals, then you can do all the work at home. To sharpen the blades yourself, you can use the following devices:

- knife sharpening machine;

- usual grinding whetstone (abrasive stone, wheals);

- emery;

- metal file;

- grinding wheel.

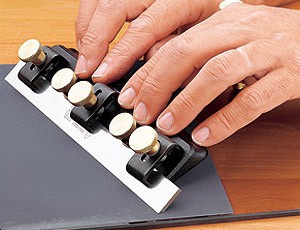

Also required special clampto keep the part being sharpened.

Grinding the blade with an abrasive stone is performed as follows.

- Remove the working nozzles that need to be sharpened from the electroplane drum.

- Fix the knives with special screws in the clamp so that their cutting edges lie in the same plane.

- The fixed blades with light pressure, smoothly lead over the surface of the abrasive, making sure that they are sharpened simultaneously.

- Inspect ground details for the presence of deviations, repeating the whole process when they are detected.

- Check the sharpness on any piece of wood.

- Install knife plates on the drum, adjusting their position.

Before performing work, it is recommended to pre-moisten the abrasive stone with water. It should be borne in mind that the coarse abrasive is intended for primary processing, and fine-grained - for finishing. It is recommended to keep the initial angle of sharpening at the blade (approximately 30 degrees).

Considered a manual way well suited for editing sharpening. If the edges are heavily blunted or have notches, then we sharpen them on the machine. In this case, care should be taken not to remove excess metal from the blades.

If a grinding wheel is used, the part removed from the drum is driven along its surface by translational movements.

With your own hands, all actions should be carried out carefully, carefully handling the blades to avoid injury. High quality honing performance will appear with experience and skills.

The condition of the electroplane knives - their adjustment and sharpness - should be checked before the processing of sawn timber. On this depends not only the quality of planing, but also personal safety. All operations for replacing, sharpening, adjusting the working nozzles should be performed only with unplugged power tools. To give the initial sharpness of the cutting edges, it is enough to use a common wheel.

/rating_off.png)