Choosing a hammer drill for home or professional use.

The puncher is the irreplaceable tool during repair of housing or at construction. With it, it is very easy to make various holes in concrete, brick or stone surfaces. To correctly select the tool for certain types of work, first of all you need to know what types of drills offers industry.

Content

Types of perforators

Although the purpose of these units is the same (drilling, drilling, chiseling), they differ in their functionality, which affects their area of application.

Cordless drills

The devices working from the rechargeable battery (joint stock bank), it is possible to carry to a category of household electric tools.

The cordless puncher is convenient to use in places where there is no electricity, but you should know that the tool is designed for a short time.. With it, you can only make a few holes in the wall. To perform work on solid materials, which imply a long operation of the apparatus, it will not work.

The main advantages of the device on the battery:

- Independence from the power grid - can be used in the country, in the garage, during roofing, etc .;

- sufficient power;

- small weight;

- compact body;

- presence of reverse;

- it is possible to drill concrete (maximum diameter 10 mm);

- It has a speed regulator.

Disadvantages of the device on the battery:

- device operation time is limited by battery capacity;

- inconvenient for frequent use, because it takes time to charge the battery;

- when falling the battery fails;

- There are difficulties when buying a spare battery.

Network devices

This type of apparatus is most sought after, both for homework, and for professional use in the construction sphere.

Due to the constant power supply from the electrical network, the units have good performance and have great power. Network perforators are widely used in construction and repair work, make it easy to drill and drill walls, as well as punch holes in them.

Advantages:

- high performance;

- affordable price;

- most of the devices have three modes of operation (drilling, drilling + blow, blow without rotating the cartridge);

- anti-vibration system;

- the ability to adjust the speed.

Disadvantages:

- power cord restricts movement;

- at unstable voltage in the network, performance decreases;

- during prolonged and frequent work, the chuck is worn out, as a result of which the fixation of the drill weakens and the cartridge needs to be replaced.

Pneumatic drills

Pneumatic tools work from compressed air. For this reason, it can only work in conjunction with a compressor.

This type of tool is used in places where electric tools cannot be used due to the explosion hazard.

Often pneumatic units are used when working in damp areas, for example, filled with water.

Advantages:

- small weight;

- high spindle speeds and high beats per minute;

- can be used in damp areas and areas with increased risk of explosion.

Disadvantages:

- operation requires a compressor;

- hose length limits movement;

- high cost of the unit.

Petrol devices

Units having a gasoline two-stroke engine as a drive have high power and high impact force.

Advantages:

- mobility thanks to independence from the compressor and the power supply network;

- one tank refueling allows the unit to work for about 2 hours;

- swipe;

- three modes of operation.

Disadvantages:

- high price;

- big weight;

- impact force is not adjustable, which may cause unnecessary cracks in the treated surfaces;

- the need for a canister with additional fuel;

- material costs for the purchase of fuel;

- large dimensions.

Classification by engine location

In addition to the power source, the devices may vary in the location of the engine: they are pistol type and barrel type.

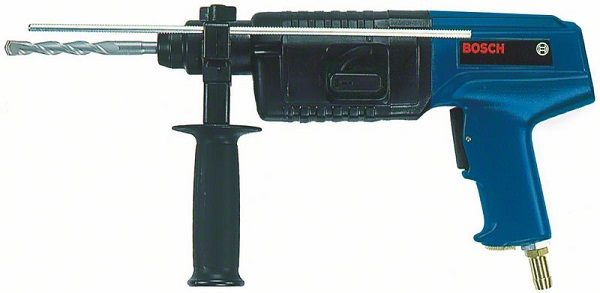

Pistol type of apparatus

In these perforators, the engine is located horizontally, and the percussion mechanism (located in the barrel of the unit) is driven by Drunk bearingwhich is transmitted rotational motion from the rotor.

Perforator-barrel

If you look at the barrel perforator, you can see that the engine is installed in it at the bottom of the unit. The vertical electric drive makes it possible to most effectively use the crank mechanism (KSHM) to engage the shock unit in the work.

Rotational motion of the rotor of the engine are transmitted to the crank, which, converting them into reciprocating motion, transmits to the piston. The latter actuates a percussion mechanism located in the barrel of the apparatus.

Important characteristics of perforators

In order not to overpay money for unnecessary power, or vice versa, not to get the desired result due to the low power of the device, it is necessary to study the main characteristics of the devices and what they affect.

Impact force

This parameter indicates with what effort the tooling (drill or peak) will be immersed in the material being processed. The impact force is measured in joules (J). The value of this indicator depends speed of work. In the professional field, you have to drill a lot of holes a day and make large openings. Therefore, it is necessary that the apparatus had a strike force from 4 to 17 J. For a home there will be enough a puncher with a strike force of 1-3 J.

Power

The impact force depends on the engine power of the unit. Perforators can be divided by power into 3 classes.

- Light devices have a small capacity, on average, up to 0.8 kW. They weigh about 4 kg and can develop a blow force up to 3 joules.

- Medium Punchers have a power of 0.8 to 0.9 kW, weigh up to 8 kg, develop an impact force of up to 9 joules.

- Heavy machines - These are devices with a power of 1.2 kW and above. They weigh more than 8 kg, and the impact energy is above 17 J.

Shock frequency

From the frequency of impacts also depends on the performance of the tool. Even when the impact force of the unit is high, with a low frequency of impacts, the work with such a tool will be slow. Therefore, this indicator is very important for professional use of a punch, and should be about 5000 beats per minute. At the same time, a home appliance may have 3-4 thousand.beats per minute

Rotational speed

This figure is significantly higher in household drills. This is explained by the fact that at home the device will be more often used as a drill. Therefore, for household devices available speed of rotation in the range of 1500-2300 r / min. For professional technology, the rotational speed of the spindle is in the range of 750-1100 rpm, since priority is given to the impact functions of the devices.

Modes of operation

Most units have 3 modes of operation.

- Hit. In this mode, the tooling performs only the movements of a progressive nature, as during the work of a jackhammer. Circular spindle movements are absent.

- Drilling The spindle of the apparatus rotates. This mode allows you to use the unit as a drill, as well as for drilling with diamond crowns.

- Drilling + hit. In this mode, combined 2 functions. It is usually used for drilling holes in solid materials using special drills.

You should know that there are models of drills that have only 1 or 2 modes. Therefore, we choose a device with three modes: with it, you can solve more problems.

Type of chuck and drill diameter

In perforators taken to use SDS cartridges. The abbreviation SDS is translated from German as “insert, rotate, fix”. Chucks are divided into 5 types:

- SDS - in this cartridge, you can insert the shank of the drill with 2 slots.

- SDS-plus - a shank with 4 slots and a diameter of 10 mm was developed for this cartridge.

- SDS-top is a cartridge for an uncommon type of shank with a diameter of 14 mm, which is used in devices of the average category.

- SDS-max is designed for heavy drills. The diameter of the shank, which can be fastened in it, is 18 mm. The shank has 2 closed and 3 open grooves and is included in a 90 mm cartridge.

- SDS-quick - equipment with shanks without grooves is fixed in this cartridge. Instead, special projections are used.

Additional options

The characteristics that were described above are key. And in order to choose the right punch, you need to pay attention to them. But there are also additional options that should be considered when buying a device, as they can significantly improve the usability.

- Presence of reverse. This option is optional but desirable. With its help it is easier to pull the drill out of deep holes.To do this, simply turn on the reverse rotation of the spindle of the machine.

- Anti-jamming. This feature is very important if you choose a high power unit. When jamming the equipment in the material being processed, a special coupling can prevent the master from being injured and the motor windings burning out.

- Speed shifter. With it, it is possible to adjust not only the speed of rotation of the spindle, but also the frequency of impact.

- Smooth start Avoids tool jerks when starting.

- Stabilization System. This function keeps the spindle speed at the same level, regardless of the load on the tool.

- Button-stopper for the switch allows you to lock the start button in the working position, and further holding it with your finger is not required.

- Anti-vibration system important for a professional tool. Thanks to her, the master will feel a much smaller vibration, which, as is well known, affects not only muscle fatigue, but also the health of the person as a whole.

- Emphasisallowing you to control the depth of drilling.

- Availability of dust collector. A perforator with a dust collector allows the master to more comfortably carry out the work of drilling the walls, since this operation produces a lot of dust. Nozzles have a nozzle for connecting a vacuum cleaner to them, and may have a different design.

The best manufacturers

The number of manufacturers of perforators is steadily increasing every year. But self-respecting professional craftsmen prefer a tool that has been tested for years in practice and has good feedback from owners. The review below includes the most popular manufacturers of devices for 2016-2017.

- It is a German company and a leader in the production of electrical equipment. Bosch tools have proven themselves to be highly reliable, functional and well-equipped. Instrument prices range from 5 to 90 thousand rubles.

- Nitachi. Japanese company, whose production is located in China. This fact mainly affects the pricing policy. The tool can be purchased at a price of 6 to 90 thousand rubles.

- The country of origin is Japan. Thanks to the release of a very high-quality tool, Makita concern conquered the markets of Europe, Asia, America and the Russian Federation.Price range from 6 to 87 thousand rubles.

- Interskol - manufacturer from Russia. In recent years, the company has gained a good reputation not only in the near abroad, but also in the Middle East and in Europe. The prices for the instrument are in the range from 3 to 30 thousand rubles.

- Bison It is also a very famous manufacturer from Russia, producing high-quality tools. It is possible to buy the puncher at the price from 3,5 to 20 thousand rubles.

Tips for choosing a device

First of all, if you are confused, which is better to buy a punch, decide for what use you want to buy a tool: for domestic or professional. Usually, household tool does not withstand heavy loads and is designed for short-term operation, no more than 25 minutes. After that, the engine must be allowed to cool down for about 30 minutes. In addition, home appliances should not work more than 4 hours (in total) per day. At the same time, a very powerful tool is not needed for home use.

Professional construction puncher can be used to perform large amounts of work, including as a jackhammer,since the unit is able to withstand heavy and long loads. It is possible to distinguish a professional puncher from a household one by several signs:

- price - household power tools are much cheaper than professional ones;

- the apparatus of the class of the pro is distinguished by great power and considerable weight;

- professional units have a high impact force, which increases their performance.

Punch for home

Tools for home use are devices of light and medium level, by weight and power. If you occasionally need to use this tool for concrete or chiselling of brickwork, then it is recommended to purchase a pistol-type machine having the following parameters and design features:

- engine power should be in the range from 0.6 to 0.9 kW;

- impact force - from 1.2 to 3 J;

- the device must have 3 modes of operation;

- impact speed can reach 5000 beats / min;

- must be adjustable spindle speed;

- spindle rotation speed should be 1100 rpm and higher;

- the presence of a coupling preventing jamming is welcomed;

- the machine must have a keyless chuck and be sold with a replaceable chuck;

- it is necessary to have a button for fixing the trigger;

- comfortable handle that rotates easily to any position;

- the presence of the reverse (the ability to enable reverse rotation of the spindle).

Punch for work

A professional rotary hammer, both with a horizontal engine and a vertical one, should be able to work within the ranges listed below (these are generalized parameters within which the tools of the pro class work):

- impact speed should be from 1000 to 5000 beats / min;

- spindle speed from 750 to 1100 rpm;

- impact force from 8 to 17.5 J;

- power consumption from 1250 to 1500 W;

- weight from 6.9 to 10 kg;

- maximum drilling diameter in concrete from 45 to 80 mm;

Also, the apparatus for professional use must be equipped with anti-vibration protection and anti-jamming.

/rating_off.png)