What are the nozzles for punch

Punching nozzles, such as drills, chisels, crowns, spikes, blades, are designed to perform a variety of jobs: drilling, drilling, chiselling. Thanks to their use, the functionality of the device has been greatly expanded. Due to the presence of impact function and high-strength, wear-resistant replacement parts, with the help of a tool you can work with solid materials. Each type of nozzle for a perforator is characterized by its design features and standard sizes. In addition to the main types offered by retail chains, there are still a number of modifications created by craftsmen at home.

Content

Boer classification

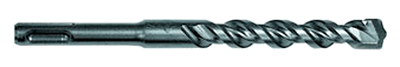

The most common among all interchangeable nozzles for punch is a drill. The rest are used in practice less frequently. Boers are composed of the following parts:

- tail (shank);

- working (with a tip).

With their help, during construction, electrical installation and other types of work, they make holes in concrete, brick, cinder block, stone, wood, metal and other materials. General view of the product is presented in the photo below.

Types of tail parts

The shank is characterized by a high degree of resistance to wear and is used to fix the drill in the punch chuck. It is made from high-strength steel grades. Allocate such types of shanks:

- Sds plus;

- Sds max;

- Sds quick;

- Sds top.

Products with designation Sds plus - This is the most common type of tail parts (c d = 10 mm and L = 40 mm) in the Boers with a diameter range of 4 ÷ 26 mm. This shank has four grooves (open type), intended to carry out the fixation in the cartridge. It is suitable for small size punch (domestic or construction).

For lugs with d 16 ÷ 40 mm (mostly over 2.6 cm) and a total length of 0.25, 0.45, 0.55, 0.8, 1.2 m, which are used in heavy punchers that have relatively high power, or bumpers with an electric motor, used tail parts Sds max. With such a shank, the diameter of the area inserted into the cartridge is 18 mm, and L = 90 mm.

Tail part with marking Sds quick intended mainly for use with Bosch rotary hammers. She has a holder and tabs. This allows you to use the bits from the screwdriver, as well as drills.

Sds top in practice, it is used and is much less common than other types of shanks for drilling nozzles with a diameter range of 1.6-2.6 cm. Its length is fixed in the chuck of the tail section is 70 mm, and d = 14 mm.

The type of shank determines the possible size of the drill.

Varieties of working parts and tips

The working part of the manufacturers are made in different forms with the use of special hard alloys. They determine the safety of using the tool and affect the speed of work.

According to their purpose, Boers are divided into the following types, depending on the form of their working part:

- augersdesigned for drilling holes in different materials of different diameters and depths, ensuring effective dust removal and thereby reducing the load on the tool;

- low inclined grooveswhich are used when drilling holes of shallow depth;

- with a large slope angle, designed for high-performance drilling at high speeds of a small number of deep holes, but at the same time, the effective working load on the tool used increases. +

Due to the presence of grooves, centering is ensured, as well as the stability of the drills when drilling holes, and vibrations are reduced. This reduces the load on the working tool.

Using a long auger, it should be borne in mind that it is more difficult for them to work than for a short one. You need to constantly observe safety precautions.

The tip is the cutting element of the drill which represents the soldering made of firm alloys. Its quality determines to a large extent the life of the nozzle, as well as the quality and speed of work. Tips in a form which has a soldering, share on such versions:

- classic (cross-shaped soldering);

- centering (with a special form of soldering).

There are also cutting edges of the waveform.

Tips are diamond and pobeditovye. Via diamond tips You can work on reinforced concrete and stone.They have a very high wear resistance and durability.

Pocket solders strength are divided into the following types:

- soft, used in drilling for brick and low-quality concrete;

- medium strength, suitable for domestic use;

- high strength, almost analogous to diamond.

Drills for concrete or other materials are divided by cost into cheap, household and professional. The latter have the highest price, but they are allowed to use even for drilling in reinforced concrete.

Difference of drills from drills

The drill and perforator drill are almost similar to each other. But they have the following differences.

- Different tail parts: at drills they are smooth, and at the drill - a complex shape.

- The ribs of the spirals in the drill are designed to be embedded in the material being processed, while in the drill they ensure the discharge of dust particles during operation.

- Different strength: it is higher in the Boers.

- The drills are suitable for both the drill and the punch (when using special adapters), and the drills are only for the last tool.

Drills are designed to work in the rotational mode, and the drills - in the shock-rotational,therefore, when drilling on metal and wood, the former are used.

What are crowns for?

The crown for the punch is an indispensable nozzle when carrying out electrical work: drilling walls for junction boxes, built-in switches and sockets. It is a shank with a cylinder fixed on it, equipped with defective teeth or diamond coating.

The table below contains varieties of crowns according to different criteria.

| Types of nozzles for different separation criteria | |||||||

| edge material | way of working | type of tail | cutting method | ||||

| diamond | pobeditovye | drums | unstressed | SDS-max | SDS-plus | to "dry" | with water cooling |

There are models with a steel cutting edge and tungsten carbide.

Diamond crowns allow you to perform work on reinforced concrete and concrete, but are expensive. They have a diameter of from 25 to 130 mm and are used mainly by professionals.

Pocket crowns differ in lower price, but they do not take reinforced walls. Their diameter is from 35 to 120 mm.

Impact nozzles are intended to be used when the perforator is operated in a rotary percussion mode.With the help of their drilled solid materials, not reinforced walls or floors. At hammerless drilling method diamond crowns are often used.

Crown nozzles with a SDS-plus shank are used for perforators with low power, and SDS-max are used in tools of greater power and size. These tails are mainly intended for hard alloy crowns. Diamond nozzles are used more often on drilling machines.

“Dry” and “wet” cooling methods are designed for various types of punchers and nozzles of various diameters. Observe the requirements for the operation of crowns set out in the operating instructions for them. This will maximize the life of the nozzle.

A number of models of corona nozzles has a drill located strictly in the center that extends beyond the working plane - such a design feature helps to accurately carry out the drilling according to the marking. The central drill acts as a guide.

The type of the tail must match the punch used in the work, otherwise you will need to use a special adapter. The crown must necessarily correspond to the material of the wall in order not to fail quickly.Drilling deep holes requires the use of extension cords. In everyday life nozzles are most often cooled by air.

Chisels, spades and paddles

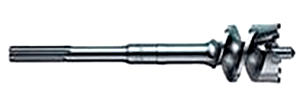

When working with a hammer drill, it is often necessary to use a chisel, a pick and a spatula. These tips are shown in the photo below.

Chisel designed for chipping concrete. The end of it is not hardened, therefore it requires periodic grinding. Often with the help of this nozzle perform the removal of old tiles and plaster. To continue the recess under the cable, use a channel chisel. The width of the working edge at the nozzle is different (a typical option is 20 mm), and the length reaches 250 mm.

To punch a hole in the walls of brick or concrete using a perforator on it set the peak. She can also do groove for pavement under the wiring. Holes obtained when working with a lance require further processing, because it is difficult to make them neatly.

For shtrobleniya walls, floors, ceilings for laying wiring used blade, having a semicircular shape. It is a cheap alternative to the wall chaser.

When choosing nozzles, first of all take into account their sizes (lengths, diameters), which should contribute to the performance of the required work with maximum efficiency. The quality of products also belongs to the leading place, because professional replacement parts become useless for a very long time even with intensive use. Despite their high price, they are recommended by experts for regular use in work. This not only increases the service life of the tool, but also the speed of work, as well as their quality.

/rating_off.png)