Device and repair of the punch cartridge

Any tool is subject to wear, and the punch is no exception in this regard. One of the most common perforator breakages is a malfunction of the chuck. Nozzles in it can badly keep, sometimes they cannot be taken. Most often this happens with improper care of the tool. Although the device of the cartridge is quite complicated, its repair or replacement is quite capable of a home master.

Content

How is the cartridge punch

Modern cartridge for punch has an SDS design. This abbreviation hides the words Steck, Dreh, Sitz. Translated from the German language, this means "inserted, turned, secured." It is in this sequence is the installation of nozzles in the punch. It does not matter the type of nozzle - a drill, a peak or an adapter for a drill.The most common types of cartridges:

- SDS-plus;

- SDS-max.

Both options provide a quick-change mode replacement nozzles.

SDS-plus

This design is equipped light perforatorsdesigned for drilling holes with a diameter of up to 20 mm in concrete or brick. On a nozzle tail four slots are located. The grooves (4) guide the movement of the nozzle when installed, they come into contact with the wedges (5) of the cartridge - this is how the working tool rotates. The grooves (2) are used for fixing the shank, they include locking balls, not allowing the drills to pop out.

SDS-max

SDS-max applied on heavy perforators. Such tools have a powerful engine with great impact force. They make holes up to 50 mm. To reduce the loss of torque, the number of grooves in it is increased. The rest of the design is similar to SDS-plus.

Other ammo

In addition to SDS, there are less common clamping designs. They are intended for fixing the tool with a smooth shank.

Key chuck for punch, it is gear-crown, similar to the standard clip for a drill. The nozzle in it is fixed by three cams, which are moved by the action of a special key.Although the nozzle is held securely, the use of such a design is limited, as the tool change takes quite a long time.

Fast-tightening designs are more convenient in work, save time spent for replacement of nozzles. AT double-muffled chuckIn order to clamp or release the working tool, you need to hold the back and rotate the front, that is, both hands are involved. One-piece design allows you to act with one hand, but requires fixing the working shaft. Such an option should be incorporated into the punch design.

Despite the convenience of keyless chucks, primacy is preserved for the design of the SDS.

SDS chuck disassembly

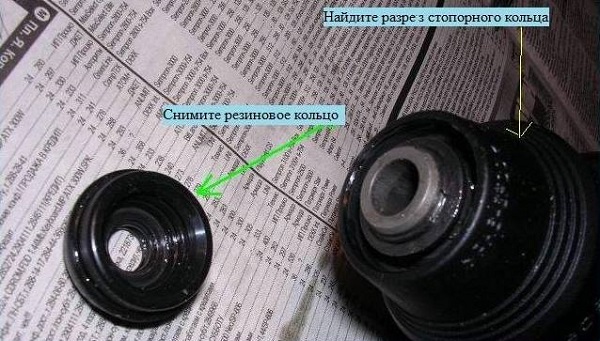

To assess the status of the cartridge punch this site must be disassembled. Begin disassembly by removing the front rubber boot. It does not fasten, just pry it with a screwdriver.

Next, remove the retaining ring and washer. So the spring is released.

Be careful when removing the spring: there are lock balls under it, they slip out easily and can be lost. After removing the spring, you can remove the rear boot.

The cylinder is fixed with four inserts, simultaneously passing through the walls of the barrel punch.Inserts are flush into the wall, grab them not for anything. The most convenient way to remove inserts a small magnet or magnetized screwdriver. The freed cartridge is removed, slightly twisted from side to side. After inspection, make a conclusion: it requires replacement of the entire cartridge or only some parts. Reassemble in the reverse order.

Typical faults in the clamping unit

Most often the following parts are faulty in the cartridge for the perforator.

- Anther has worn out or has cracks, which is why building dust penetrating into the cartridge contaminates the lubricant and prevents rotation.

- Retaining ring. Its weakening frees the spring, the balls fall out of the grooves, the drills do not hold.

- Guide cylinder. The wear of the internal grooves does not reliably fix the drills.

- Spring. Its wear or rift reduces depreciation.

- Balloons. Reducing their diameter due to wear does not allow to hold the drill.

Balls, spring and retaining ring can be replaced with suitable-sized parts from other mechanisms or try to make yourself. The anthers and guide cylinder are not repaired, they will have to be replaced with branded serviceable copies.

All necessary parts are sold in specialized stores.

As you can understand, the repair of the cartridge punch is not so difficult process. After the end of the warranty period for the tool in case of breakage, the puncher can be repaired on its own, without contacting the service center.

/rating_off.png)