Causes of washing machine buzz during washing

All appliances produce a certain sound when working. But loud noises when washing should already lead to certain thoughts about breakage. The user should not ignore the question of why the washing machine is buzzing - you should definitely get puzzled with the answer and find the right solution.

Content

Noise levels

The noise level of the washing machine a specific model is prescribed in its instructions. It depends on the cost of the drive:

- in the belt variant its variations are from 60 to 72 dB (decibel);

- at direct drive the threshold is reduced from 52 to 70 dB.

What do these numbers mean? That the user will still hear the work of such a device, and absolutely noiseless washing machines does not exist. The technique works, but such audibility should not create discomfort. If such a feeling arises, the device is clearly inoperative. And well, if the reasons are not very serious.

Noise due to improper installation

Why is such a technique buzzing? If such a "concert" occurs already at the first launch, it is necessary to conduct such a check.

- See if unscrewed shipping bolts. Often this embarrassment happens to newbies for installation, who decided to hold it without the presence of a master. It is enough to subject the device to inspection - the notorious bolts are located at the rear of the case. Their task is to properly fix the drum when the device is moved to a new home. When installing the bolts are removed, and instead of them are installed plastic plugs that come with the device.

- Technique must be installed on smooth and hard floor.

- Be sure to adjust legsso that the machine does not stagger during operation. It will be enough to turn them in the direction necessary for balance. Can be used anti-vibration stand.

Unscrew shipping bolts

Fail noise

Sometimes the sound discomfort in the washing machine appears only at certain stages of its work. Perhaps the point is this:

- In the case emerged cracks at the location shock absorbers or legs.

- At the drum pulley loose. This is solved quite simply - the back cover is removed and the corresponding part is tightened.

- The same effect is caused and loose bolts on the engine backlash. Here too, a simple reinforcement of fasteners will suffice.

- Cracks in the tank require its replacement (and it is better to let a specialist do it).

- Upper springs they can also be loose, as are the fasteners holding the counterweight. All this is solved by simple fixation.

Much of the above can be eliminated independently, without resorting to the services of professionals.

How to remove a strong rumble when working machinery

Bearing replacement

If the machine has become very noisy, the fault may be hidden in the bearings. It is quite simple to check this hypothesis - it is necessary to turn the drum with the machine turned off manually. If the process was quiet, then you need to sin on other broken parts. In the case when the guesses were confirmed, the following should be done.

- The front wall is removed (locking screws follow the cuff, the bottom panel and the control panel are removed).

- Removing the back wall - you need to carefully unscrew the screws.

- Removed TEN, which is the engine. He, too, will need to be pulled out, having previously removed the belt.

- It is necessary to disconnect the tank, which is attached to the body with springs and shock absorbers.

- How to disassemble the tank? Usually it consists of two halves bolted together.

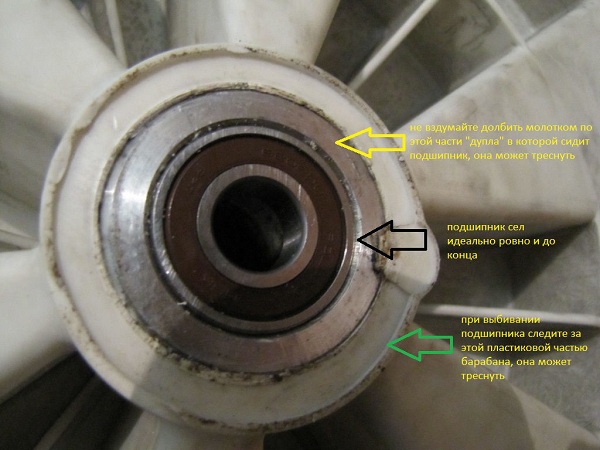

- Worn out bearings are knocked out and they are replaced with new ones.

- Everything is going in the opposite direction.

Usually the wear of such parts appears after aging. packing gland - it is this part that is responsible for sealing the tank. When moisture leaks, the bearings start to rust and wear out quickly.

The process of replacing bearings for different brands is described in more detail in our articles on washing machines. Samsung, LG, Indesit, Ariston.

Foreign objects

Technique can make a loud noise for another banal reason - there was a foreign object in the drain pump. Often this indicates inconstancy loud sounds emanating from the wash: they will resemble a crack.

Under foreign objects can be understood bones from the bra, coins, buttons and other small metal objects. Removing them will be easy:

- It is necessary to loosen the mount. Heating element and pull it out.

- With the help of tweezers, the objects caught in the pump are obtained from the hole.

- The heater is installed back in place, the rubber seal is lubricated with a liquid detergent.

Usually, the drain pump can fail after only five years of operation of the washer, and foreign objects in it will only accelerate the process.

By the way, it is not recommended to replace and disassemble the drain pump without the help of a professional. But if the user is determined to do it on his own, this video will be useful to him:

Washable cuff

Washing the washing machine at the very wash is also because sometimes the sealing cuff starts to rub too vigorously on the drum. This moment will indicate rubber crumbs on the surface of the door. You can try to deal with such a misunderstanding on your own (a method not always justified by experts):

- A piece of sandpaper of the middle or small fraction is fixed on the side of the drum with the help of an adhesive tape.

- Technique runs on push up mode.This trick will cause the paper to strip the cuffs at the points of contact with the tank.

- The machine starts to rinse - it will clean the equipment from the inside of rubber dust.

Loose pulley

If the sounds are intermittent clicks, then you can suspect a loose drum pulley mount. This is not surprising: it can gradually become loose. To rid the part of free play, the loosened bolt is unscrewed and placed on the sealantthat will prevent from re-easing.

How to secure the drum pulley

Counterweight broken

A washing machine is often noisy due to balances. These details are needed to give sustainability baku in the process of push-ups. Sufficient weight of such elements perfectly balance the tank on both sides. What you need to know about balances? The difficulty is that there are such details in hard to reach places. To inspect them, you need to help yourself with a flashlight. And it is also assumed manual research - after probing the loose places are tightened. In any case, if integrity counterweights broken in order to prevent the destruction of the tank, they should be changed.

Worn brushes

The car buzzed, but it does not twist the drum - here you can suspect worn out brushes in an electric motor. Knocking in such cases is usually very loud. The work associated with this replacement will best be entrusted to a specialist. This is due to the fact that the machine will have to completely disassemble, removing the motor.

The user must learn: the noise coming out of the machine is a signal of a malfunction. Especially if this hum is abnormal. It is necessary to timely diagnose and fix all the problems that have arisen.

/rating_off.png)